Jason Schulze, Conrad Kacsik Instruments, Inc.

Jason Schulze, Conrad Kacsik Instruments, Inc.

This is the third in a series of articles by AMS 2750 expert, Jason Schulze. Please submit your AMS 2750 questions for Jason to Doug@HeatTreatToday.com.

Introduction

Of all the changes made to AMS2750 through the years, the Alternate Systems Accuracy Test (ALT SAT) is arguably the one that has had the largest impact within the heat treat industry. The requirements for the ALT SAT, as presented in AMS2750E, make up just 0.008% of the specification as a whole; yet these requirements account for an inordinate amount of time spent on discussion and debate.

Below, we’ll discuss the requirements of the ALT SAT as they are presented in both AMS2750E, and in the Nadcap Pyrometry Guide.

ALT SAT Applicability

Prior to revision E of AMS2750, a load thermocouple that was single-use, or which was replaced more often than the applicable SAT frequency, did not require an SAT of any kind. During the time period when Revision D was in effect, the Alternate SAT did not exist. This meant that if you used a load thermocouple and had a documented single-use statement or replacement schedule, which ensured the usage did not exceed the applicable SAT frequency within your internal procedures, that particular load sensor was not subject to the SAT requirements of AMS2750D.

AMS2750D page 14, paragraph 3.4.1.2

3.4.1.2 An SAT is not required for sensors whose only function is over-temperature control, load sensors that are limited to a single use (one furnace load/cycle), sensors not used for acceptance as part of production heat treatment, or load sensors whose replacement frequency is shorter than the SAT frequency. See 3.1.8.4 and 3.1.8.5.

When AMS2750E replaced AMS2750D, the ALT SAT was introduced. In addition to the ALT SAT, paragraphs 3.4.4 through 3.4.4.3 were also inserted:

AMS2750E pg 19, para 3.4.4

3.4.4 The SAT can be accomplished using any one of 3 methods:

3.4.4.1 Perform an SAT following the requirments in 3.4.5

3.4.4.2 Alternate SAT process defined in 3.4.6

3.4.4.3 SAT Waiver process, as described in 3.4.7

By stating that the SAT “…can be accomplished using any one of 3 methods”, this section has often been misinterpreted to mean that a supplier may simply choose which type of SAT they wish to implement. This is not the case.

An ALT SAT must be performed on any thermocouple that is either

- single use, or

- replaced more often that the applicable SAT frequency.

Throughout the industry, these two items typically apply to load thermocouples. As an example, let’s assume that a non-expendable load thermocouple is used in a furnace that is designated as a Type A, Class 5 furnace. This would put the standard SAT frequency at quarterly (no SAT extension & parts-furnace). If the non-expendable load thermocouple that was used had a documented replacement frequency of monthly, the ALT SAT requirements would apply to this particular load thermocouple.

In the example above, a supplier could not accomplish the SAT “…using any one of the 3 methods” – the ALT SAT requirements would be required for that particular load thermocouple system and would need to be accounted for in the supplier’s internal pyrometry procedure.

ALT SAT Requirements

The ALT SAT requirements can be split up into a single main requirement and two sub-requirements which suppliers may choose to implement. The main requirement is:

- Calibration of instruments at the point at which the sensor is connected.

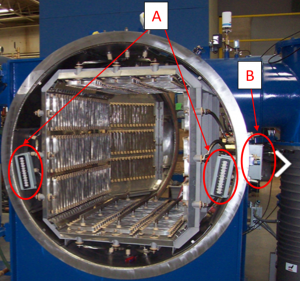

This means that, wherever the thermocouple is connected directly, instrument calibration must take place at this point. Let’s look at a vacuum furnace as an example.

Location A indicates where load thermocouples will be plugged in directly. Location B is where the extension wire from inside the furnace travels to the outside of the furnace and then on to the recording instruments. Location A is where the calibration of the recording instrument must take place per the ALT SAT requirements. This requirement in no way changes the standard requirements for instrument calibrations as they are presented in AMS2750E; it only specifies exactly where the instrument calibration must take place within the furnace sensor system. Your internal pyrometry procedure must state that this is a requirement.

The next paragraphs, 3.4.6.1.1 & 3.4.6.1.2, are where the supplier must read and understand both paragraphs in order to make a choice regarding which option best suits their furnace set-up and production. Let’s break both paragraphs down.

Option Number 1

3.4.6.1.1 - Establish appropriate calibration limits for sensors which when combined with the calibration of the instrument/lead wire and connector, will meet the SAT requirements of Table 6 or 7, as appropriate.

There are several ways to go about conforming to this paragraph. Keep in mind, that when choosing an option you are dealing with 2 variables; the error of the instrument which records the thermocouples in question and the error of the thermocouples themselves.

a) This option relieves you of one of the variables stated above. When calibrating your instruments which the thermocouples are plugged in to, ensure there is absolutely no error at all. Adjustments (offsets) may need to be made to accomplish this. This means that, if you do not permit offsets currently, you will either need to account for them in your procedures or choose option “b” below. Once you’ve established that your instrument has no error, you restrict the error of the thermocouples you purchase not to exceed the appropriate SAT difference stated in Table 6 or 7.

As an example, let’s assume you have a vacuum furnace that uses 2 load thermocouples which are single use only. The furnace is classified as a Type A, Class 2 furnace – this means the Maximum SAT difference is ±3°F or 0.3% of the reading. You would ensure that the recording instrument for those 2 channels recording the load temperature have no error. Then, order load thermocouples which have an error of ±3°F or 0.3% of the reading, or less.

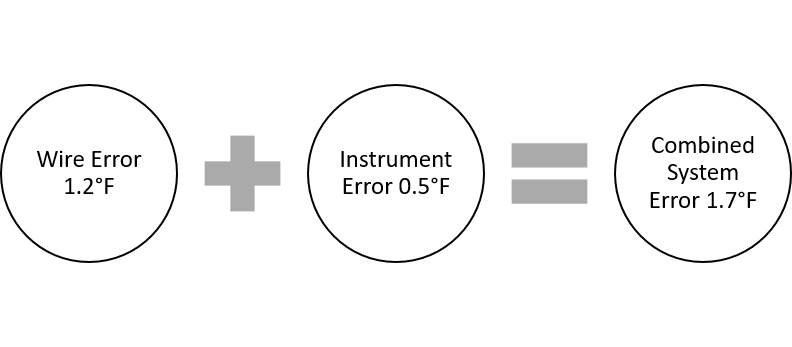

b) This option is most attractive to those who do not wish to allow offsets within their heat treat operation. To accomplish this, you compare the error of the specific channels of the instrument the thermocouples in question plug into, to the error of the thermocouples themselves. The resulting value cannot exceed the maximum error permitted for the appropriate furnace class. Internal pyrometry procedures specifically state how thermocouple wire will be received and the ALT SAT calculation accomplished prior to releasing the thermocouple wire to production. There are two variables that must be verified in this option. Anytime one of these two variables change, the calculation must be obtained. The Nadcap Pyrometry Reference Guide requires that this calculation be evaluated at the instrument (chart recorder) calibration points (min, max & middle 1/3rd.)

For Your Consideration

There has been some confusion in the industry that the ALT SAT process, specifically Option B above, must be accomplished at the furnace. This misunderstanding includes suppliers using a Field Test Instrument to simulate the min, max and middle 1/3rd of the instrument calibration temperatures in an effort to obtain the error of the instrument channels in question. This amounts to nothing more than an additional instrument calibration; one could simply obtain the error from the current instrument calibration instead of performing extra work at the furnace.

Option A and B above would be performed as a desk operation; none of the tasks would be performed at the actual furnace.

Conclusion

The ALT SAT process has been successfully implemented by many suppliers in the Aerospace Industry; both Nadcap approved and non-Nadcap. As with any AMS2750E process, detailed procedures and training are key to executing the ALT SAT process.

Submit Your Questions

Please feel free to submit your questions and I will answer appropriately in future articles. Submit your questions by sending an email to doug@heattreattoday.com.