![]() State of Industry 4.0 in the North American Heat Treat Market: What’s Being Done and Who’s Using It?

State of Industry 4.0 in the North American Heat Treat Market: What’s Being Done and Who’s Using It?

What is “Industry 4.0” and how is this new technology being used in the heat treat industry? Industry experts spoke with Heat Treat Today about their involvement with this cutting-edge application of technology. To learn how you can implement Industry 4.0 at your plant, read what experts have to say about the problems, solutions, and the future of Industry 4.0.

In this Heat Treat Today Original Content article, Peter Sherwin at Eurotherm, Aymeric Goldsteinas at Ipsen, Robert Szadkowski at SECO/WARWICK Group, and Dan Herring at The HERRING GROUP, Inc. bring varied perspectives as they tackle this topic.

“I think IoT should be better applied – period!”

– Peter Sherwin, Global Business Development Heat Treatment Executive, Eurotherm

Industry 4.0 and “the internet of things” (IoT) were hot topics in the crammed online chatrooms of this year’s heat treat events. But exactly what are these technologies in the world of heat treat? What are the current applications that three leaders in Industry 4.0 have applied? What are some problems and solutions that this new tech brings? And lastly, what is the future of Industry 4.0?

This article will begin by explaining and defining a few prominent technologies before answering each of these questions. Then, read a few thoughts from The Heat Treat Doctor® as you think about application to your heat treat process.

What Is It and Why Does It Matter?

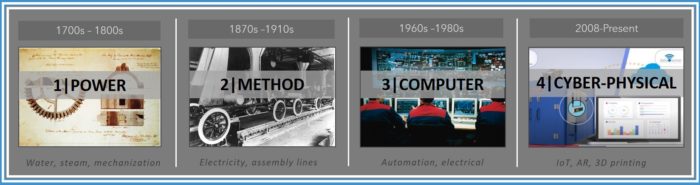

Basically, the term “Industry 4.0” refers to the Fourth Industrial Revolution. See the chart for a breakdown of major topics of the first three industrial revolutions.

The idea of new communication is sometimes referred to as cyber-physical connections. This is occurring right now! For example, a sensor (cyber) can monitor a furnace (physical) and send information about the furnace’s conditions to a central data sorting location (connection) for a human to synthesize and respond. The Fourth Industrial Revolution – Industry 4.0 – refers to how the communication between the physical world and the digital world are seamlessly connected.

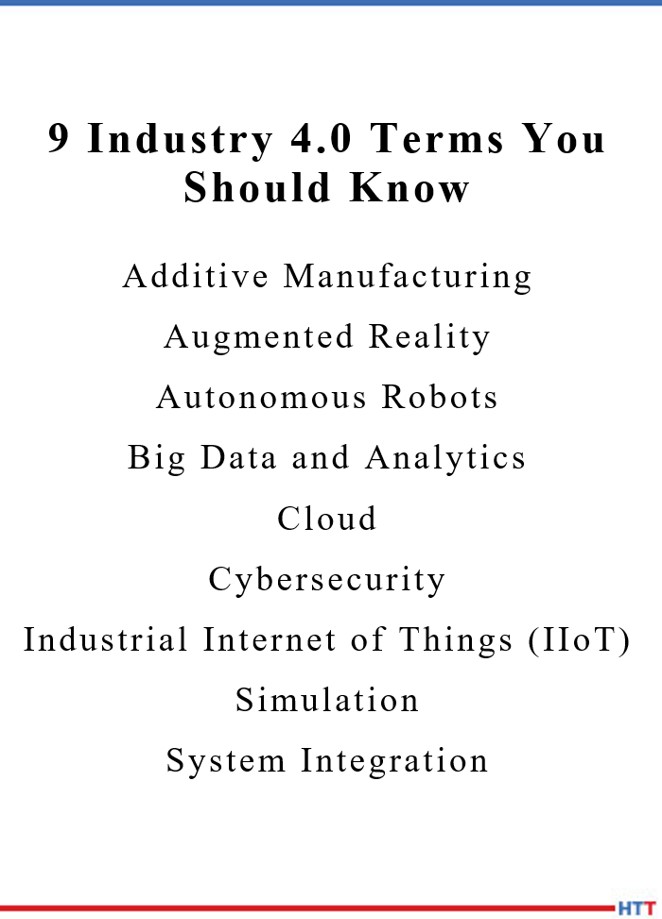

A key feature of Industry 4.0 is the internet of things (IoT), but other technologies like artificial intelligence (AI), augmented reality (AR), virtual reality (VR), and machine learning also play a part. Let’s define a few of these Industry 4.0 terms that you will see later in the article:

- IoT: refers to the physical networking of objects via internet-supported software. Similarly, the “industrial internet of things” (IIoT) refers to these systems supporting industrial purposes, like synthesizing information from furnace sensors on a central app.

- artificial intelligence (AI): machines which can process and perform complex directions in a way that mimics natural intelligence.

- augmented reality (AR): digital enhancement of a real-world environment. Think of phone apps which can portray a digital overlay on a video feed, like Snapchat lenses.

- virtual reality (VR): digital experience that may be interactive with the real-world environment, or completely simulated.

- machine learning: an extension of AI, machine learning describes the result of computer algorithms which modify their performance based on repeated input.

While engineers have been pursuing these new applications for several years, COVID-19 has been a driving factor for businesses to pursue technical options in their daily operations due to limits on travel and physical contact.

[blockquote author=”Robert Szadkowski, VP of Aftermarket Sales, SECO/WARWICK Group” style=”1″]Remote acceptance testing is a highly requested service today. I could say that the financial rationale for such action has always existed, while the epidemiological threat has been the catalyst for change. It is a win-win action.[/blockquote]

According to Aymeric Goldsteinas, project development manager at Ipsen, customers are becoming more willing to implement Ipsen’s Industry 4.0 endeavors, even cloud-based solutions, a willingness that was not present just one decade ago. So how is the heat treat market responding?

Current Applications

We asked suppliers how they implemented Industry 4.0. What follows is how they responded.

Ipsen | PdMetrics

Source: Ipsen USA

Ipsen launched a software system in 2016. The company continues to develop and improve its predictive maintenance capabilities to service many of their current customers.

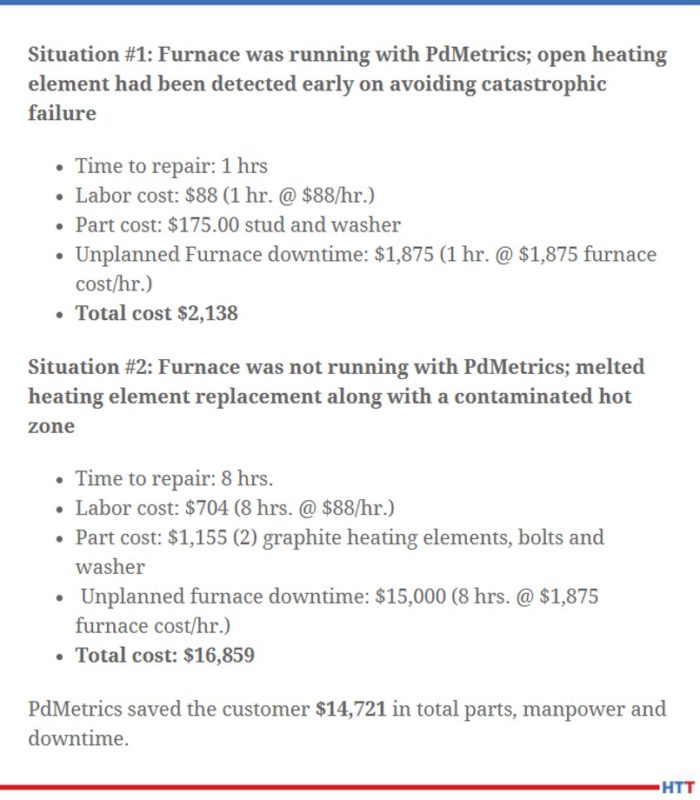

Part of the system’s customer appeal, said Aymeric Goldsteinas, product development manager at Ipsen, is that it can “minimize high-cost events and maximize furnace up-time.”

This is done by using sensor technology and gathering data in their PdMetrics database, which then anticipates future furnace problems. This reduces unplanned downtime and could help heat treaters avoid scrapping loads of high-value parts.

From a consumer perspective, this IoT technology solution leads to improved part quality and part performance.

How it works: PdMetrics assigns a variety of sensors to each system in the heat treat process. For example, a quench system sensor checks vibrations, cooling motor temperature, and water temperature.

Click the image to read 5 case studies on PdMetrics.

On Ipsen’s client digital dashboard via PdMetrics, Goldsteinas showed the heat treating systems depicted with a green-yellow-red gauge to portray the working condition of that system. Green indicates that the system is well-maintained, yellow indicates a system needs to be maintained soon, and red means that maintenance is needed immediately. This easy-to-use display is also an example of how Industry 4.0 technologies create user-friendly experiences and cut out excess human input.

This product was used by an aerospace manufacturer to update their systems, integrating this software with their heat treatment process. The results were noticeably increased efficiency of parts and less unplanned downtime. The company was able to schedule maintenance at off-peak hours and plan for future needs by using the platform’s ability to identify maintenance trends, deteriorating conditions, and more.

Check out the post to the side to see how a heat treater was able to save thousands to tens of thousands of dollars with PdMetrics system.

While this company has set the pace with their early adoption of IoT in the heat treat industry, it is worth noting that other companies also offer similar products.

Eurotherm | Cloud-based advisors, visualization software, edge-computing technology

Source: Eurotherm.com

In 2013, Eurotherm began their transition to IoT technologies.

“One of our first true cloud-based solutions focused on improving the efficiency of the calibration process,” said Peter Sherwin, global business development heat treatment executive of Eurotherm. He continued, “This system connects third-party calibration providers with their end-customers and provides an enterprise-wide web view of the calibration status (via dashboards) and access to reports. The smart-tablet app provides an easy-to-follow workflow for conducting a compliant calibration and produces an instant report along with the associated QR-code label.”

Referring to their web-based systems and use of cloud platforms, Sherwin said, “along with our parent, Schneider-Electric, we have developed a range of edge-computing solutions to allow simple transfer of data from the plant-floor to cloud-based advisors and visualization software.”

Sherwin says that their systems are being used globally. “Our enterprise calibration platform,” he shared, “is being utilized by several partner companies as well as in Schneider Electric GSC (Global Supply Chain) Manufacturing plants worldwide.”

Sherwin also noted a variety of IoT applications that Eurotherm provides:

- A cloud-hosted digital services platform, EcoStruxure™ Manufacturing Compliance Advisor uses asset compliance to “reduce testing costs, increase productivity and be audit-ready with a robust scheduling and testing process.”

- A system called EcoStruxure™ Machine Advisor “allows OEMs to track, monitor and fix equipment remotely.” Additionally, operators can predict and execute maintenance schedules, which improves machine availability.

- On a mobile device, EcoStruxure™ Augmented Advisor combines “contextual and local information… creating a fusion of the physical, real-life environment with virtual objects.”

Case in point: “An OEM machine manufacturer in the ceramics industry helps customers reduce their energy consumption by 30% by leveraging our IoT software,” Sherwin shared.

SECO/WARWICK | Remote Factory Acceptance and Activation Tools

Source: SECO/WARWICK

Recently SECO/WARWICK publicized the fact that they successfully conducted several international and remote factory acceptance tests. Two customers from China, one from South Korea, and one from Mexico all participated. Each customer was able to remotely approve the furnace construction and performance work of their new furnaces while the furnaces were still on the shop floor in SECO/WARWICK’s European manufacturing facility. No customer engineers were involved on-site at the factory.

Recordings from individual cameras, sensors and viewfinders were downloaded to secure servers and made available to customers. The tests were successful, and the adopted procedures guarantee the reliability and completeness of the data, according the company report.

The company has been using these technologies for “internal device supervision for at least ten years,” according to Robert Szadkowski, VP of Aftermarket Sales at SECO/WARWICK. “In our work,” he continued, “we use remote supervision tools and applications, we report overall equipment efficiency (OEE) indicators, and we conduct optimization processes in terms of batch queuing or energy factor consumption.”

Szadkowski at SECO/WARWICK remarked that for most systems, distance furnace commission is very likely. He explained, “It starts at the stage of making arrangements regarding the expected technical and technological parameters, continues throughout the production and commissioning period, and then during the warranty and post-warranty period. The participation of the customer, the end user of the furnace, in the acceptance tests is required, as is training of the operating personnel […]. There are exceptions to this when dealing with high-risk systems, but for many systems this would be perfectly acceptable.”

Still, Szadkowski noted that “this will be primarily a challenge to our ideas and internal acceptance, rather than to technical limitations.”

C3 Data | End-User System Compliance

Finally, the C3 Data application for furnace compliance is an example of an interrelated, stream-lined, digital solution that provides customers with clear, “real-time” data.

12 Second SAT.mp4 from C3 Data on Vimeo.

Digitizing data ahead of time integrates testing processes. The system scheduler allows compliance tests to be planned ahead of time. Digitizing the calibration data allows for technicians to scan QR codes attached to test instruments and test sensors to access that data as they test for compliance.

When compliance is tested, the results are immediate for the technician and the quality assurance manager (QAM). The technician uses a portable device to complete these tests, scanning the test instrument and the test sensor, and then inputting the stabilized temperatures from the test instrument and the furnace instrument. In twelve seconds, a technician can complete a system accuracy test (SAT); watch the video above to see the SAT Additionally, the system automatically populates paperless reports to be signed and sent to the QAM. This allows the quality assurance manager to check the reports in real time.

Similar to earlier products, a digital dashboard depicts furnace compliance data. The graphic visualizations allow users to quickly evaluate which furnaces are in compliance, and, if not, why.

Problems // Solutions

Businesses have experienced a few problems with integrating the technology. But there are solutions.

Product Development Manager

Ipsen

Source: padtronics.com

The first problem is data storage. Like all storage, data storage is finite, and therefore costly. The use of interrelated systems that require high volumes of data to flow between sensors and central systems necessitates investment on the front end for storing data. Additionally, having limited bandwidth to keep digital communication lines open can cause blackouts and connectivity issues. But after acquiring storage, there are practices to use that storage as efficiently as possible.

A solution that Ipsen implements to alleviate this active/working storage stress is “the frequency rule.” This rule establishes a rate of data movement to allow data to move across system memory.

A second issue is privacy/security. It is necessary that the heat treater’s product or process data is properly secured, and while the supplier has certain responsibilities to mitigate this issue, heat treaters should be aware of ways to safeguard their intellectual property. One option, which Ipsen suggests, would be to purchase a unique VPN to ensure better data security. Some companies, including Ipsen, use a stand-alone system that works independent of the PLC, which ensures proprietary data is kept private while following secure industry software standards.

A third issue is user acceptance or, simply put, how comfortable you are with 4.0 technologies. If a heat treater is not comfortable with the technology itself, then Industry 4.0-related tech can be more difficult to implement. On the flip side, suppliers — regarding all processes — must be ready and able to meet the customer’s demands for new products, as Dan Herring, The Heat Treat Doctor®, has indicated. (Ref. 5) An example of digital demands is the AMS2750F requirement that paper chart recorders be replaced with digital data acquisition systems by June 29, 2022.

User acceptance relates to the final problem: relationship with the supplier. While not a bad thing in and of itself, if your relationship with your supplier is not good, then it will be a challenge to develop an effective Industry 4.0 solution process. Be sure you develop an open, communicative relationship with your supplier so that they can offer you unique solutions for your plant’s operation.

The Future of Heat Treat

Here are some interesting applications that people in the industry are looking to with the progression of Industry 4.0:

1. Increased Servitization

Director, Vice President of the Aftermarket Sales Segment

SECO/WARWICK

Source: Robert Szadkowski

Szadkowski at SECO/WARWICK emphasized that these rapid changes to heat treat systems makes it likely that the servitization — the selling of services rather than products — of the heat treat industry is likely to develop in the near future.

“I am strongly convinced,” Szadkowski wrote, “that sooner or later the servitization will cover the heat treatment industry. When looking at the potential benefits, it’s basically inevitable. The customer, user of the furnace, will be able to focus on their core business instead of worrying about the operation of the furnaces. The manufacturer of the device will be keenly interested in ensuring that its furnace works flawlessly (so that the availability is as high as possible) and brings business benefits to the user. What’s more, with a correctly prepared PaaS (Product as a Service) contract, the OEM will also be interested in improving the operating parameters of such a device after delivery.”

He continues that “Such solutions have existed in the industry for years, e.g. the Rolls-Royce model of selling aircraft engines known as Power-by-the-Hour. The benefits are on both sides; both parties can focus on what they are best at and what is their core business, reducing costs and increasing efficiency. Both parties are interested in long-term cooperation, not a one-off transaction. In light of global problems with access to service engineers, including maintenance staff, the shift of responsibility for the operation of devices from the user to the manufacturer is a natural direction of change.”

2. Augmented Reality / Mixed Reality / Virtual Reality Glasses

There are a few hypotheses revolving around the use of AR service glasses. SECO/LENS augmented reality is currently being explored. This would help in providing remote field service support to the heat treater.

Ipsen’s Goldsteinas has also noted several benefits. He explains the application working by connecting a customer or field service engineer who is at the site with an expert from Ipsen or another service provider. This remote assistance wherein an informant is able to see a problem and give first-hand direction is a common example used to describe the benefits of AR. This application could, for example, decrease the down-time if a furnace were to unexpectedly fail.

Additionally, Goldsteinas envisions training sessions that are conducted in mixed reality. Using virtual reality with an oculus — a type of goggle that digitally enhance or recreate a digitally interactive, environment — companies could reduce training time by recreating experiences, like meetings or practical training sessions, that could be collaborative or solitary. Mixed reality devices like the HoloLens may also be integrated for similar purposes. (Watch video to the right to see examples of Microsoft’s HoloLens and other enhanced reality examples.)

5 examples of #AugmentedReality and #VirtualReality #technology changing the way we #learn and #work #VR #AR #IoT #AI #FutureofWork #DigitalTransformation #CES2021

cc @GlenGilmore @SpirosMargaris @jblefevre60 @Paula_Piccard @pascal_bornet @kuriharan— Harold Sinnott #CES2021 ? (@HaroldSinnott) December 13, 2020

The future could also involve virtual collaboration in the form of an augmented reality meeting room to allow employees from across different Ipsen facilities to discuss and interact with the same content in real-time

3. Efficient Cloud Capabilities

Peter Sherwin personally foresees that attention to the Cloud’s abilities and security will be leveraged in new ways: “An example of this is looking at some of the cost-effective modern-day instrument SCADA [supervisory control and data acquisition] offerings that can provide an on-premise hub for certain applications while managing security policies for linking to cloud based IoT offers.”

4. Increased Systemwide Application

Specifically looking at IoT technologies, Sherwin shared, “I think an expanded view of IoT that encompasses automation across the enterprise (termed as Intelligent Automation or Hyperautomation) is more useful if you really want to achieve significant returns on investment [of IoT technologies]. IoT solutions can improve speed and reduce costs across sales, operations, maintenance, quality, service and administration.”

Advice: To Use or Not To Use

The Heat Treat Doctor®

Dan Herring, The Heat Treat Doctor®, has written about Industry 4.0 and how thinking about seven considerations in any continuation of or change to one’s heat treating process is essential. Ask yourself:

- Do I understand what I want to accomplish metallurgically?

- Can I predict the outcome of the heat treatment operation?

- Can I build repeatability into the process?

- Am I using state of the art heat treating equipment?

- Am I aware of changes to manufacturing operations?

- Am I compromising on quality?

- Do I know the costs?

At the end of the day, noted The Heat Treat Doctor®, heat treaters need to know that what they are doing is being done the right way, the first time with the best procedures and processes for their particular operation.

Reflections on The Heat Treat Doctor®

Peter Sherwin of Eurotherm commented on the seven-part advice of The Heat Treat Doctor®, noting, “I think it is very appropriate to look at the value of IoT through the seven considerations that [he] outlines. Building these solutions requires heat treat know-how and an understanding of the data to be captured in order to provide valuable solutions. Value is unlocked in the following categories:

- “Right first-time quality improvements. A good heat treater will have quality costs <1% of turnover. The MTI suggests that the cost of quality (all activities) can hit $750k for a decent-size heat treat operation. The knock-on [effects] of poor quality impacts customer satisfaction through delayed deliveries and costs in rework/rejects.”

- “Maintenance. These costs can fluctuate – but lets assume a well run plant with fairly modern equipment has costs around 5% of turnover. Significant purchase/cost savings can be made via remote support as well as an understanding of remaining useful life of key components (and avoiding panic purchases).”

- “Energy. Again this can fluctuate, but let’s say 10% of turnover. Modern efficient solutions (gas or electric) can significantly reduce the cost of energy and this can be further optimized via IoT solutions.”

- “Labor Costs. Say an average of 20% of turnover. Some of the modern XR offers (Extended reality – covers AR, MR, VR etc.) can definitely speed up training, help retention of knowledge, and reduce the time and costs in troubleshooting as well as aiding remote support.”

“It won’t be too long before IoT offers enhanced decision support to heat treaters to aid making profitable decisions,” Sherwin concludes.

Concluding Thoughts

Global Business Development Heat Treatment Executive

Eurotherm

Whether we like it or not, Industry 4.0 related digital integration is becoming essential rather than simply a better option. Again, the recently published AMS2750F revision highlights this shift for heat treaters.

[blockquote author=”Peter Sherwin, global business development heat treatment of Eurotherm” style=”1″]I think it is important that we use IoT where it can truly bring value and don’t view it as a silver-bullet for everything.[/blockquote]

That does not mean you need to scramble to jump on the bandwagon, but strategically assess your position, your operations, and your options to identify what option is best. Look to other examples in the industry and heat treating tech insiders to inform these new, powerful realities.

Read/Watch More:

- Pascal Bornet, Ian Barkin, Jochen Wirtz, Intelligent Automation. Suggested by Peter Sherwin at Eurotherm.

- C3 Data testing video, “12 Second SAT (C3 Data FNA 2020).” Vimeo. https://vimeo.com/462483080/50e1e1e490

- IIoT World, “Augmented Reality in Manufacturing: implementations that provide the most benefit,” YouTube (15 November 2018). https://www.youtube.com/watch?v=njOMv1liNag&ab_channel=IIoTWorld.

- Lindsay Glider, “Rockwell Automation’s 4-Step Guide to Starting Your Digital Transformation Journey,” com (13 October 2020). https://tinyurl.com/yynfoufs.

- Aymeric Goldsteinas, “Optimizing Thermal Processing Operations with Predictive Maintenance Software,” IpsenUSA.com. https://www.ipsenusa.com/resources/articles-and-white-papers/optimizing-thermal-processing-operations-with-predictive-maintenance.

- Dan Herring, “Industry 4.0 and Seven Key Considerations.” Industrial Heating (November 2017).

- Bernard Marr, “What Is Industry 4.0?,” YouTube (July 11, 2019). https://www.youtube.com/watch?v=yKPrJJSv94M&ab_channel=BernardMarr.

- Metal Treat Institute, “FNA 2020 Virtual Session: Jack Kalukci – Nitrex Metal,” YouTube. (Sep 29, 2020). https://www.youtube.com/watch?v=mZ5ipkj44-0&feature=emb_logo&ab_channel=MetalTreatInstitute. This video explains IIoT networks very well and describes the human factors needed in integrating these solutions.

- NASSCOMVideos, “Unlocking the Value of Industry 4.0 with 5G,” YouTube (Oct 13, 2020). https://www.youtube.com/watch?v=2sQr9fkLbRM&ab_channel=NASSCOMVideos

- Ted Institute, “Markus Lorenz: Industry 4.0: how intelligent machines will transform everything we know,” YouTube (Sep 4, 2015). https://www.youtube.com/watch?v=uBZmJOHIN8E&ab_channel=TEDInstitute.

- Image References: https://www.loc.gov/resource/cph.3b51661/; https://www.loc.gov/item/2011661021/; https://en.wikipedia.org/wiki/Process_control#/media/File:Leitstand_2.jpg; and https://www.heattreattoday.com/equipment/heat-treating-equipment/ovens-high-temperature/wisconsin-oven-introduces-iot-technology-for-industrial-oven-performance-monitoring/.