Ask The Heat Treat Doctor® has returned to bring sage advice to Heat Treat Today readers and to answer your questions about heat treating, brazing, sintering, and other types of thermal treatments as well as questions on metallurgy, equipment, and process-related issues.

This informative piece was first released in Heat Treat Today’s November 2025 Annual Vacuum Heat Treating print edition.

Case depth, case uniformity, and final mechanical (as well as other) properties rely not only on controlling both equipment and process variability during heat treatment, but on having clean, properly prepared part surfaces prior to and during heat treating. Expert Dan Herring encourages to learn more below.

Case hardening is a thermochemical surface treatment process designed to add a particular element or combination of elements to a material such as steel. Familiar examples include carbon (carburizing); carbon and nitrogen (carbonitriding); boron (boriding); nitrogen (nitriding); and nitrogen and carbon (nitrocarburizing — ferritic or austenitic). These processes are typically designed to increase the near surface hardness of steel after quenching.

However, various problems can arise due to either the materials or the manufacturing methods employed prior to or during heat treating that will retard or prevent absorption and/or diffusion of the desired element(s) during heat treating. Some of the metallurgical consequences can include:

- Shallow or uneven case depths

- Surface oxidation

- Intergranular oxidation or decarburization

- High levels of retained austenite

- Soft spots due to incomplete hardening

Machine-Induced Surface Conditions

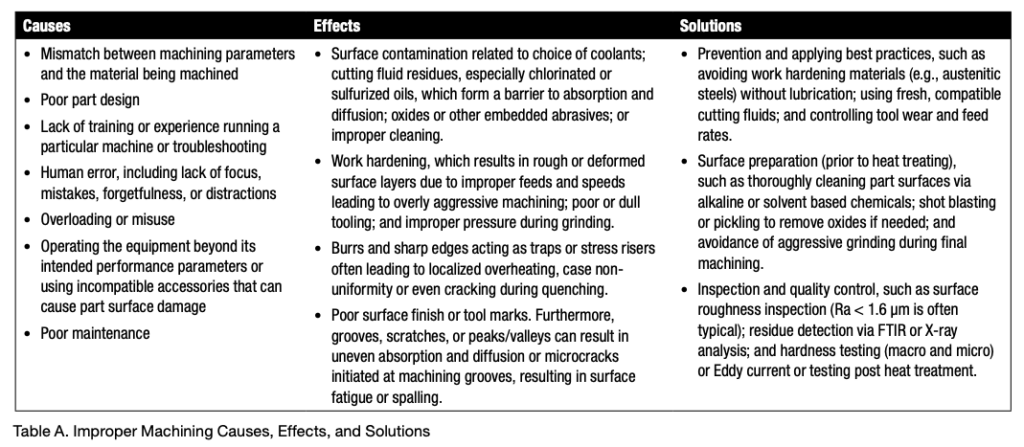

Improper machining prior to case hardening can compromise surface integrity. Tooling choices, improperly maintained equipment, inadequate operator training, and even environmental factors can contribute to a variety of issues.

While machining problems occur frequently, they are mostly preventable. Attention to part surface condition, cleanliness, and mechanical integrity is essential before heat treating. Training, standardizing machining protocols, planned preventative maintenance programs, and part inspection prior to heat treating will help avoid these issues. Consult Table A for further details on how the causes and effects of undesirable machine-induced surface conditions can be solved.

Splatter of Stop-off Paints on Unintended Areas

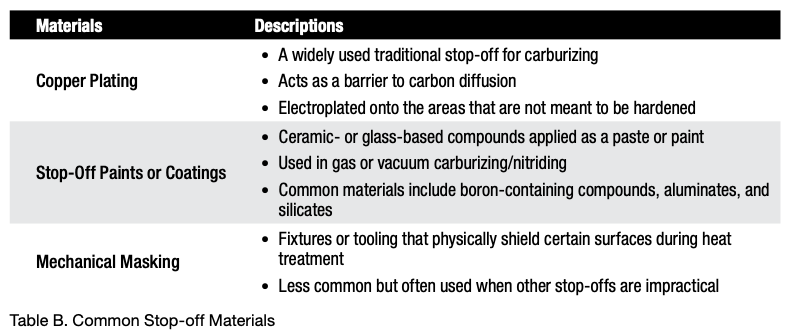

A material that masks the surface of steel and delays or prevents case hardening is called a stop-off or maskant. These materials are applied to specific areas of a steel part to prevent the diffusion of hardening elements (like carbon or nitrogen) into the surface during case hardening processes, such as carburizing, nitriding, or carbonitriding. (See Table B.)

Enriching Gas Additions (Sooting)

During the carburizing or carbonitriding process, it is not uncommon to develop a layer of soot on the surface of the parts, especially if the enriching gas additions begin before the entire load is uniformly up to temperature. In some instances, the amount of soot formation is such that the case depth or uniformity is affected. This is often difficult to diagnose, as the soot layer “washes off” during quenching in a liquid, and the part surfaces come out of the furnace looking reasonably clean.

Material-Related Issues

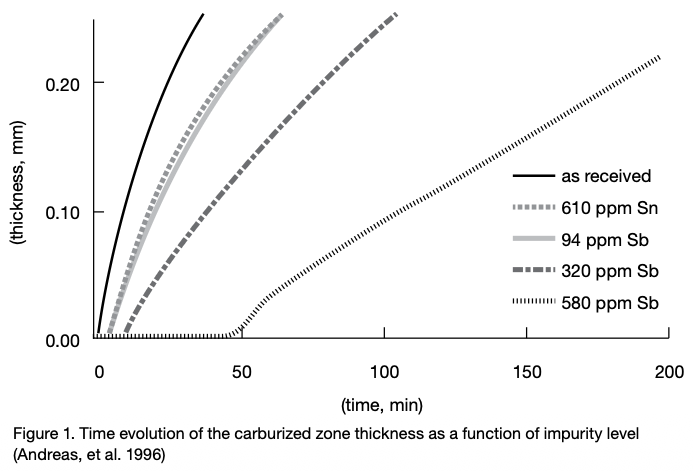

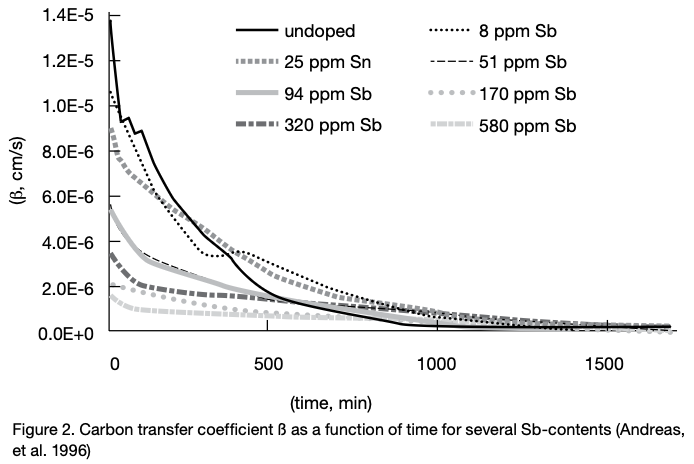

The use of scrap in steelmaking, especially for low alloy case hardening steels can lead to a relatively high level of impurities and tramp elements. At high temperatures these impurities tend to segregate at grain boundaries and migrate toward the surface. This type of segregation can retard case hardening by impeding element (e.g., carbon) transfer. For example, the effects of tin (Sn) and antimony (Sb) on the kinetics of carburization are particularly problematic (Figure 1).

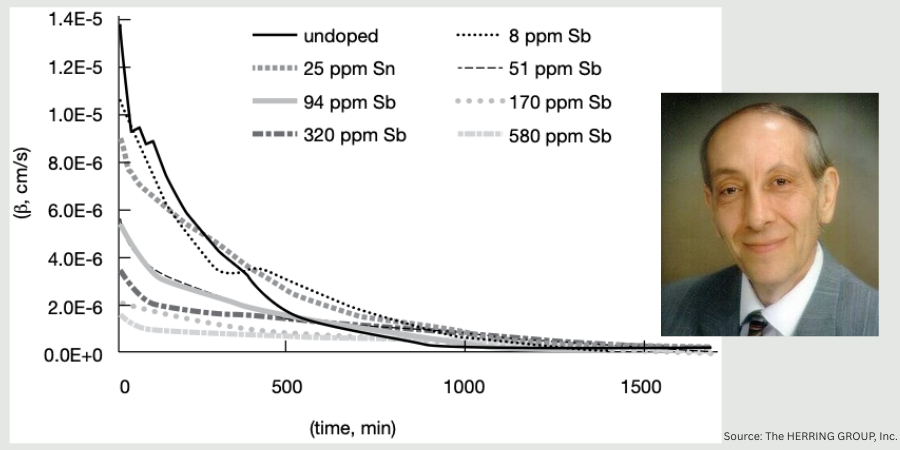

The effect of tramp elements on retardation of carburization can be expressed in the following order (Andreas, et al. 1996), namely Sb > Sn > P > Cu > Pb. To see the effect of one such element, the carbon transfer coefficient (ß) for typical commercial steels is shown as a function of antimony (Sb) content (Figure 2).

In Summary

These are a few of the many causes delaying or preventing case hardening from being effective. There are many others, including alkaline cleaning compounds (in too high a concentration) and even phosphate and other drawing lubricants used in the manufacture of fasteners. Inspection and cleaning of the part surface prior to case hardening will avoid many of these issues. Reviewing material certification sheets for elements known to interfere with case hardening is also an effective way to anticipate problems with case hardening.

References

Herring, Daniel H. 2014. Atmosphere Heat Treatment, Volume 1. Troy, MI: BNP Media.

Herring, Daniel H. 2015. Atmosphere Heat Treatment, Volume 2. Troy, MI: BNP Media.

Ruck, Andreas, Monceau, Daniel, and Grabke, Hans Jürgen. 1996. “Effects of Tramp Elements Cu, P, Pb, Sb, and Sn on the Kinetics of Carburization of Case Hardened Steels.” Steel Research 67 (6): 242–48.

About the Author

“The Heat Treat Doctor”

The HERRING GROUP, Inc.

Dan Herring has been in the industry for over 50 years and has gained vast experience in fields that include materials science, engineering, metallurgy, new product research, and many other areas. He is the author of six books and over 700 technical articles.

For more information: Contact Dan at dherring@heat-treat-doctor.com.

For more information about Dan’s books: see his page at the Heat Treat Store.