The Heat Treat Doctor® has returned to offer expert advice to Heat Treat Today readers and to answer your questions about heat treating, brazing, sintering, and other types of thermal treatments as well as questions on metallurgy, equipment, and process-related issues.

This informative piece was first released in Heat Treat Today’s June 2025 Buyers Guide print edition.

As we talked about last month, stress relief is a controlled thermal process in which fabricated material (e.g., machined or welded) is reheated to a temperature below its lower critical temperature and then held at that temperature for a specified amount of time before being slowly cooled. Post weld heat treating (PWHT) is a good example. Let’s learn more.

Why PWHT After Welding?

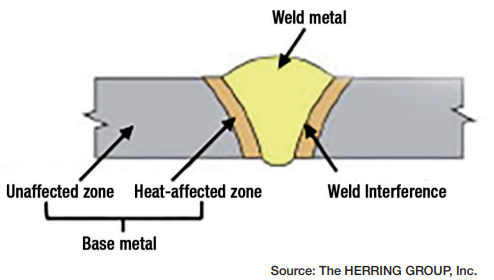

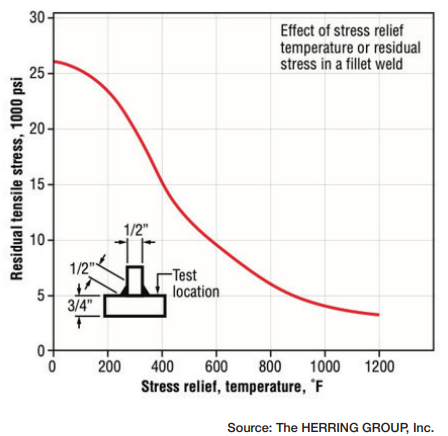

Thermally induced stresses are produced in the weld itself — in the heat-affected zone (HAZ) and in the adjacent base metal (Figure 1) — during welding and need to be relieved to avoid cracking and other modes of failures during final fabrication or service.

Purpose of PWHT

The primary purpose of PWHT is to help prevent welds in fabrications from cracking (i.e., becoming brittle). It also increases the resistance to stress corrosion cracking (SCC) and lowers the risk of hydrogen-assisted cracking (HAC) (i.e., hydrogen embrittlement) caused by high levels of hydrogen released during the welding process. PWHT can also act as a method of hardness control and enhance material strength.

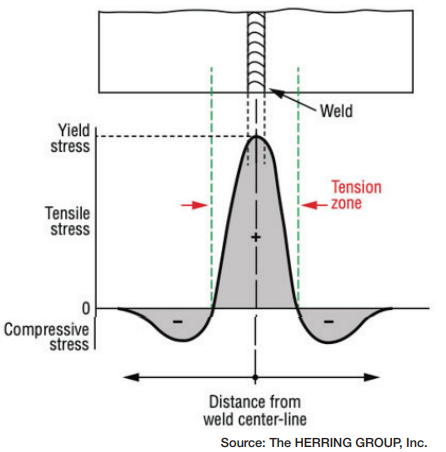

Residual stress present from welding may occur because of the high thermal gradients that develop during heating and cooling of the material. This is especially true during welding due to expansion of the material in some areas and localized contraction in other areas, resulting in the presence of surface tensile and compressive stresses (Figure 2).

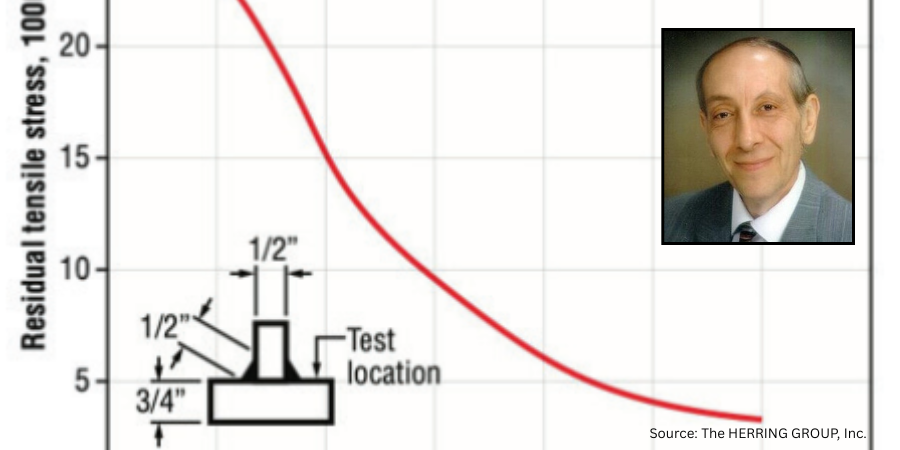

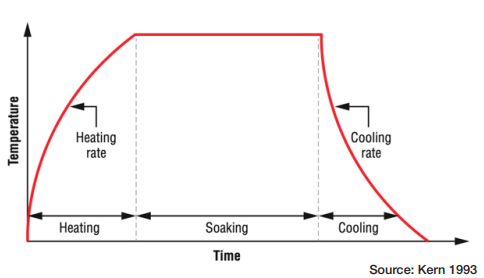

These thermal changes produce undesirable residual stresses. PWHT reduces the intensity of these changes by heating the material (uniformly) to a specific temperature, holding at that temperature, and then bringing back to room temperature at a specific cooling rate (Figure 3).

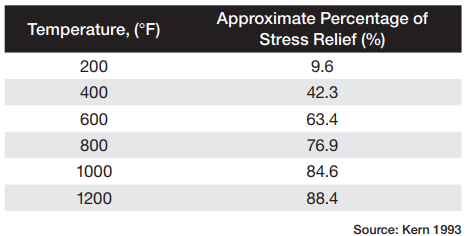

PWHT can be performed over a variety of temperature ranges: low temperatures (300 – 400°F), intermediate temperatures (900 – 1000ºF), or high temperatures (1110 – 1250°F). The temperature, time at temperature, and total cycle time determine the amount of stress that can be removed (Figure 4, Table 1).

Key PWHT Process Parameters

Key process parameters include adequate part support (remember, steels have lower yield strength at high temperature) and control of:

• Heating rate to avoid uneven thermal expansion

• Soak time to equalize temperature

• Temperature gradients to avoid hot spots from developing

• Cooling rate to avoid formation of brittle structures

What Steps Are Involved in PWHT?

Step 1: Heating

The rate of heating is typically based on the component’s thickness and often specified by the customer or company doing the work (internal standards). If the rate of heating is not performed properly (i.e., if heating is too quick or uneven), temperature gradients can form within the component and introduce undesirable thermal stress. As a result, stress cracks may occur, and residual stresses not previously present can develop when the component is cooled to ambient temperatures.

Step 2: Holding at Temperature (Soak Temperature and Time)

Soak time is governed by material thickness and part thickness. Longer holding times are needed for thicker materials to allow the material to reach a stable condition where the distribution and levels of stresses become more uniform and decrease. The specified holding temperature is one that is high enough to relieve the high residual stress state yet still below the lower critical temperature (Ac1).

Step 3: Cooling

The cooling rate must be controlled to avoid any detrimental temperature gradients that could cause cracking or introduce new residual stresses in the material during cooling. Rapid cooling rates can increase hardness, which may increase the susceptibility of a brittle fracture.

Additional Benefits of PWHT

PWHT can result in other benefits, such as softening (tempering) of the component part. Tempering the part and the weld heat-affected zone provides protection against brittle fracture failures during service.

PWHT can also improve part machinability (for subsequent manufacturing operations). PWHT tends to (slightly) reduce the degree of hardness, so components can easily be machined to required dimensional tolerances. Softening parts allow for easy grinding, machining, and other surface treatments.

PWHT Tips

If necessary, PWHT can be performed multiple times without changing or diminishing the benefits of the process. PWHT may be repeated for power failures, loss of workload thermocouples, burner malfunctions, control instrument glitches, or furnace component failures.

More than one part can be subjected to PWHT at any one time. PWHT can be performed in different types of ovens and furnaces, with box or pit styles and carbottom styles being predominant choices due to the size of many weldments.

Process monitoring can be performed using workload thermocouples attached to the parts undergoing PWHT to check and ensure that heating rates, hold temperatures, and cooling rates meet specification requirements.

Summing Up

PWHT can be applied to both ferrous and non-ferrous alloys and is intended primarily to remove internal residual stresses generated by prior manufacturing processes. Without it, subsequent processing may give rise to unacceptable distortion and/or the parts can suffer from a variety of service-related problems. The treatment is not intended to produce significant dimensional changes (although this can occur) or alter the material’s microstructure or mechanical properties.

References

Ahmed, Khaleel, and J Krishan. “Post-Weld Heat Treatment – Case Studies,” BARC Newsletter, pp. 111-115. 2002.

“An Overview of Stress Relief & Heat Treatment Processes.” DBI, Inc. https://www.dbindt.com.

BorTec GmbH & Co. KG. https://www.bortec.de/en.

Olson, D. L., G. R. Edwards, S. Liu, and T. A. Siewart. ASM Handbook. 10th ed. Vol. 6: Welding, Brazing, and Soldering. ASM International, 1993.

Bryson, William E. Heat Treatment – Master Control Manual. Hanser, 2015.

Croft, D N. Heat Treatment of Welded Steel Structures. Woodhead Publishing Limited eBooks, 1996. https://doi.org/10.1533/9781845698812.

“Heat Treatment of Welded Joints – Parts 1–3.” TWI Global. https://www.twi-global.com.

Herring, Daniel H. Atmosphere Heat Treatment: Atmospheres, Quenching, Testing. Vol. 1. BNP Media, LLC, 2014.

Herring, Daniel H. Atmosphere Heat Treatment: Atmospheres, Quenching, Testing. Vol. 2. BNP Media, LLC, 2015.

Kern Roy., “Ask Roy”, Heat Treating, February 1993

Krauss, George. Steels: Processing, Structure, and Performance. ASM International, 2015. https://doi.org/10.31399/asm.tb.spsp2.9781627082655.

Lyman, Taylor, ed. Metals Handbook. 8th ed. Vol. 6, Welding and Brazing. American Society for Metals, 1971.

Thielsch, Helmut. Defects and Failures in Pressure Vessels and Piping. Malabar, FL: Krieger Publishing Company, 1977.

Oluyemi, O., et al. Process Variables and Post Weld Heat Treatment Effects on Steel Welds. Saarbrücken, Germany: LAP Lambert Academic Publishing, 2012.

“Overview of Post Weld Heat Treatment (PWHT).” Inspectioneering. Accessed June 10, 2025. https://www.inspectioneering.com.

Weld Geometry and Postweld Heat Treatment of a Medium Carbon Steel: Effect on Mechanical Properties. Saarbrücken, Germany: LAP Lambert Academic Publishing, 2013.

Welding Inspection. Miami, FL: American Welding Society, 1980.

WTIA. “Guidance Note 6: Post Weld Heat Treatment of Welded Structures,” 2003.

About the Author

“The Heat Treat Doctor”

The HERRING GROUP, Inc.

Dan Herring has been in the industry for over 50 years and has gained vast experience in fields that include materials science, engineering, metallurgy, new product research, and many other areas. He is the author of six books and over 700 technical articles.

For more information: Contact Dan at dherring@heat-treat-doctor.com.

For more information about Dan’s books: see his page at the Heat Treat Store.