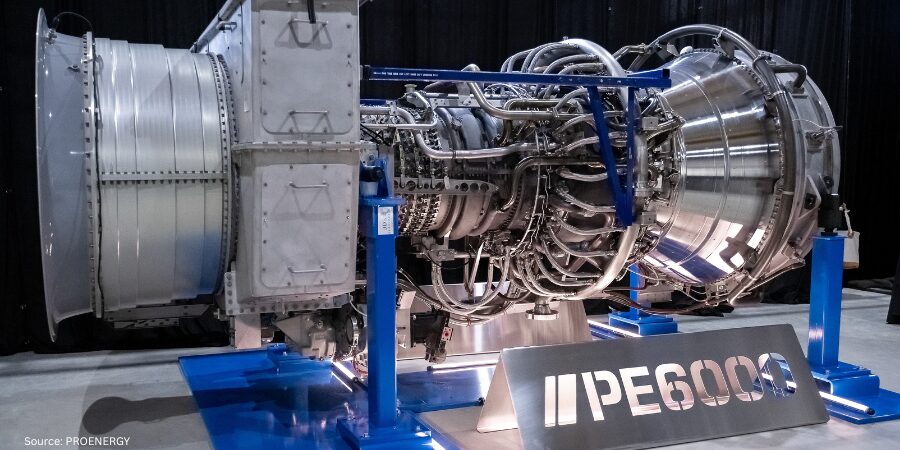

A manufacturer of heavy duty gas turbines has ordered a vacuum furnace with screen insulation and molybdenum heating elements. Siemens Energy Global will be provided the furnace by a company with U.S. locations and it will be used mainly for brazing gas turbine hot path parts like blades & vanes.

Vice President of the Vacuum Segment

SECO/WARWICK

Siemens Energy Global has chosen SECO/WARWICK to provide the vacuum furnace. The device on order includes a mechanical pump, an efficient Roots pump, and a diffusion pump. The molybdenum heating chamber ensures a required temperature distribution and provides process cleanliness.

“The Vector vacuum furnace solves the partner’s problem of heat treating an increased number of large blades & vanes requiring a high degree of cleanliness in both the brazing and annealing processes. The Vector will relieve the production burden on the current equipment in operation in the client’s manufacturing & repair facility in Berlin.” said Maciej Korecki, vice president of the vacuum segment, SECO/WARWICK Group.

Sales Manager

SECO/WARWICK

“We used a molybdenum heating chamber, partial pressure system, dew point sensors, and a very efficient high vacuum system. An important aspect is also the fact that the furnace will be integrated with the client’s master system using the OPC Unified Architecture communication protocol. Thanks to this, we can connect with a wide range of machines and industrial devices,” commented Grzegorz Głuchowski, sales manager for SECO/WARWICK.

The heat treatment processes associated with this furnace are benefited by the ability to cool at 1.5 bar in argon.

Press release is available in its original form here.