Nitrex Metal supplied three supersized nitriding heat treatment systems to US commercial heat treater Nitrex Inc., which recently completed phase one of a 12,000 square foot (1115 m2) expansion at its facility in Aurora, Illinois, a town on the outskirts of Chicago. The expansion has increased the plant’s nitriding capacities to accommodate parts up to 177” (4.5 meters) long and loads of up to 25,000 pounds (11,300 kg). All systems are equipped with NITREG® nitriding/nitrocarburizing technology, making it possible to meet AMS 2759/10 specifications for nitriding and AMS 2759/12 for ferritic nitrocarburizing. Additionally ONC® technology is available for in-process post-nitriding and -nitrocarburizing oxidation to enhance the corrosion resistance of an already treated part.

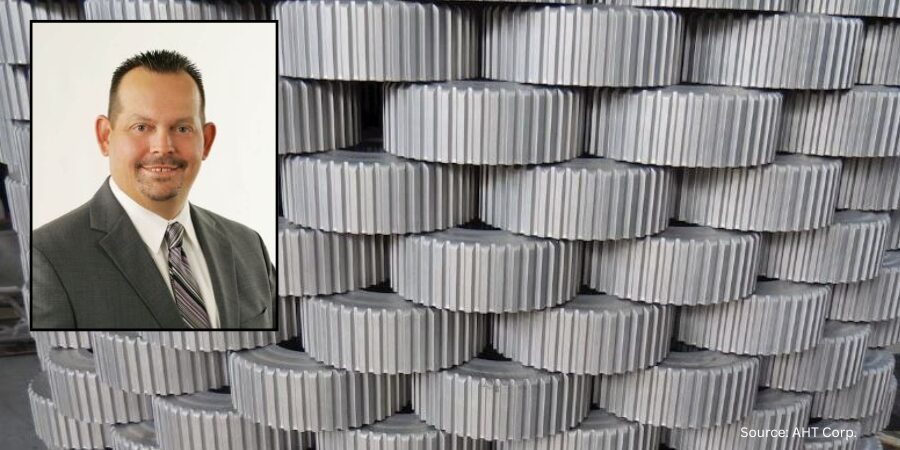

According to Tom Copper, General Manager of Nitrex Inc. – Chicago Operations, the primary motivation for the capital upgrades at his plant was that “Nitriding large diameter parts and gears had been limited to furnaces in captive heat treat shops. The same is true for long parts, tubes or shafts. Our new nitriders provide a solution to this underserved market segment.” Along with the new furnaces, phase one of the expansion involved the addition of a new two-story office building and an upgraded metallurgical laboratory.

In the second phase of expansion, the Illinois facility will add another large nitriding system from Nitrex Metal, with a working envelope of 137” Ø by 98” height (3.5 m Ø x 2.5 m H), and a load capacity of 55,000 pounds (25,000 kg). This furnace will offer the same NITREG® process capabilities and will be equipped to meet aerospace standards. The furnace is expected to commence production by January 2017.