In today’s News from Abroad installment, we highlight new partnerships and technology aimed at efficiency and sustainability; a multi-organization collaborative work on a hybrid facility, an all-in-one machine that performs hot and cold forming for screws, tubes, and spokes, and a Turkish steel expansion doubling production. Read more below!

Heat Treat Today partners with two international publications to deliver the latest news, tech tips, and cutting-edge articles that will serve our audience – manufacturers with in-house heat treat. Furnaces International, a Quartz Business Media publication, primarily serves the English-speaking globe, and heat-processing, a Vulkan-Verlag GmbH publication, serves mostly the European and Asian heat treat markets.

A collaboration for an innovative reuse strategy

“To support the growing activity at its Valenciennes site, Stellantis has chosen ECM Technologies to assist with the relocation and retrofitting of a heat treatment installation for vacuum carburizing. Scheduled to be fully operational in 2025, this hybrid facility, composed of reused, retrofitted and new components, reduces Stellantis’ carbon footprint while increasing its production and the performance of its industrial equipment. Stellantis has around 15 ECM Technologies “Flex” low-pressure carburizing units spread across its various sites. To support the production needs of its Valenciennes site, the company has decided to give a new lease of life to a line already in service within the group by entrusting ECM with the implementation of the project: relocation, reuse, updating of equipment, acquisition of new components (latest-generation gas quenching module), and conversion of furnaces from propane to acetylene, Bringing the performance of the entire hybrid system up to state-of-the-art standards. Another major factor is that this installation is part of the energy transition, as this transformation will enable the production of mechanical parts for electric vehicles, whereas previously the facility was dedicated to the production of manual gearboxes for combustion engine vehicles.”

READ MORE: Stellantis and ECM Technologies: An exemplary collaboration for an innovative reuse strategy at prozesswaerme.net

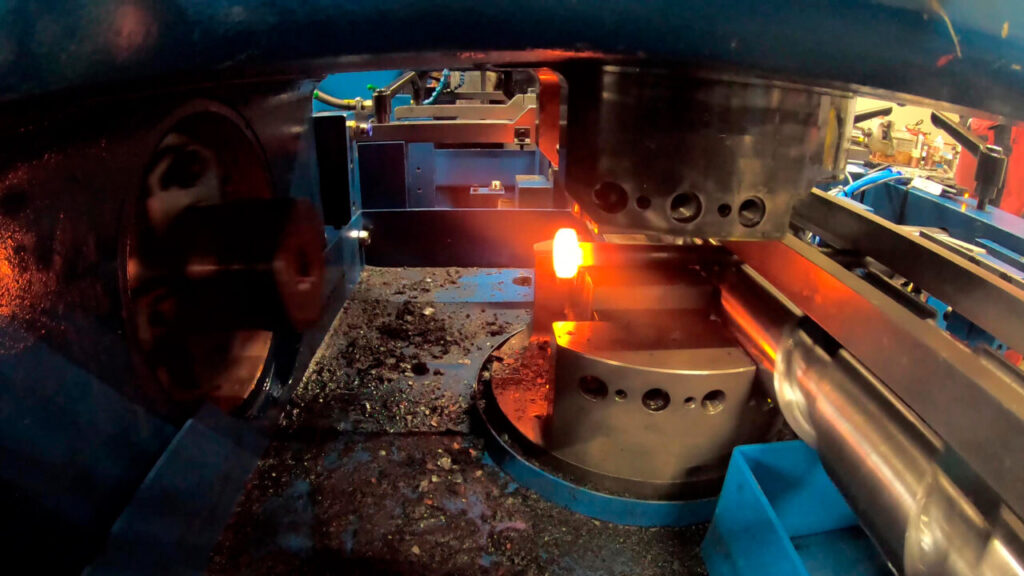

All-In-One Machine: Cold And Hot Forming

Source: VIP Communication

“Aachener Maschinenbau GmbH (AMBA) has so far been known for its all-in-one machines for the production of components such as screws, tubes and spokes by cold forming. What is new is that the company is integrating more and more technologies into its systems that enable operators to produce components such as special screws or pipes with variable cross-sections more efficiently. A current example is the integration of induction heating in the forming of large screws. With new systems, AMBA enables customers to produce more components with complex geometries according to the all-in-one principle and thus reduce costs. In doing so, the company goes beyond traditional cold forming and integrates innovative technologies, including for hot forming.”

READ MORE: AMBA offers new possibilities for efficient production: cold and hot forming of screws, tubes and spokes at prozesswaerme.net

Concast continuous casters to increase billet and bloom production capacities

“İzmir Demir Çelik Sanayi A.Ş (IDC), a manufacturer of reinforcing steel and profiles, has expanded its steelworks with a Concast seven-strand continuous caster at its plant in Aliağa, İzmir, Türkiye. This new machine provides izmir Demir Çelik with the flexibility to efficiently meet diverse market demands, while also increasing production capacity and enhancing the quality of billets and blooms. The installation of the new continuous casting plant significantly expands izmir Demir Çelik’s annual steel production output from 1,550,000 tons to approximately 3,100,000 tons. This increase enables IDC to meet growing market demands more effectively while reducing its dependence on imported semi-finished products. The new caster’s ability to produce billets and small blooms in six distinct section sizes, ranging from 150×150 millimeters to 220×280 millimeters, gives IDC the flexibility to adapt quickly to changing market needs . . . Internal quality is enhanced through electromagnetic stirring (M-EMS) and modular wave stirring (MWS) technologies, which guarantee a homogeneous internal structure. Additionally, precise strand guidance, accurate cooling spray alignment, and a three-zone secondary cooling system further improve billet and bloom quality. This innovative setup enables IDC to produce high-quality steel products efficiently while reducing operational costs and meeting diverse market demands.”

READ MORE: izmir Demir Çelik Sanayi A.Ş. uses Concast continuous casters to increase billet and bloom production capacities at prozesswaerme.net