A new testing device has been introduced by an Israeli precision laser specialist group that can determine the Start and Finish Af (martensite-to-austenite transformation) temperatures for each of several devices, of different shapes at the same time.

The noncontact Af tester (NCAT), a novel bent and free-recovery device, was recently unveiled by ANV Laser of Petah Tikva, Israel.

Prior to the testing process, the nickel-titanium test specimen is cooled to its nominally fully martensitic phase, then is deformed by bending, and finally is heated to its fully austenitic phase while the motion (recovery) of the specimen is measured and plotted against the temperature.

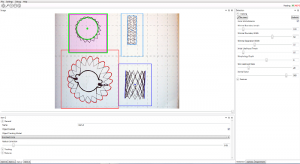

The NCAT’s proprietary image processing software automatically detects the boundary of each of the fully annealed or heat-treated nickel titanium items placed in the chilled test tray. In the user-friendly graphic interface, the tester easily deletes any non-item artifacts that were detected, and then chooses – per object — the area detection method for the test, such as inscribed or described circle, parallel lines, object boundary, and so on.

The tester then defines, for each object, the minimum and maximum boundaries for Area (to be plotted on the Y axis) and Temp (to be plotted on the X axis). The tester can also determine the rate of heating that will be generated by the NCAT’s unique heating mechanism. When satisfied with all parameters, the tester initiates the test and an Area/Temp graph is plotted for each object.

When the temperature reaches the user-defined end-temperature, the test stops automatically. The test plot for each item can be saved as a report that shows its Area/Temp graph and the calculated StartAF and FinishAF temperatures.