During the day-to-day operation of heat treat departments, many habits are formed and procedures followed that sometimes are done simply because that’s the way they’ve always  been done. One of the great benefits of having a community of heat treaters is to challenge those habits and look at new ways of doing things. Heat Treat Today’s 101 Heat Treat Tips, tips and tricks that come from some of the industry’s foremost experts, were initially published in the FNA 2018 Special Print Edition, as a way to make the benefits of that community available to as many people as possible. This special edition is available in a digital format here.

been done. One of the great benefits of having a community of heat treaters is to challenge those habits and look at new ways of doing things. Heat Treat Today’s 101 Heat Treat Tips, tips and tricks that come from some of the industry’s foremost experts, were initially published in the FNA 2018 Special Print Edition, as a way to make the benefits of that community available to as many people as possible. This special edition is available in a digital format here.

Today we continue an intermittent series of posts drawn from the 101 tips. The tips for this post can be found in the FNA edition under Vacuum Furnaces, Radiant Tubes, Combustion, and Thermocouples.

Heat Treat Tip #15

Heat Treat Tip #15

Shut the Door, PLEASE.

Minimize the threat of water vapor by keeping the vacuum furnace door closed in between cycles (especially if it’s wet or humid outside) and keeping the furnace under vacuum between cycles.

Submitted by Ipsen USA

Heat Treat Tip #16

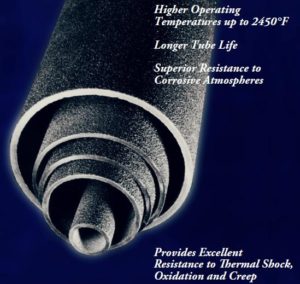

Where NOT to Use Silicon Carbide Radiant Tube

Although silicon carbide radiant tubes crank out twice the heat flux of radiant tubes and last decades longer than many alloy tubes, there are SOME places where these tubes should not be used. If any of the following apply to your heat treat situation, you should avoid these tubes; if not, you might want to put them to the test. Don’t use a silicon carbide radiant tube if . . .

1. Whenever there is a high probability that the tubes will be bumped either by the load or loading mechanism.

2. Whenever there is a high probability that parts will fall on the tube you will either have to shield the tube or avoid them altogether.

Submitted by INEX Inc.

Heat Treat Tip #17

Yin & Yang of Maintenance & Production

We all know that today’s plan is only current at the time it was made. Our industry dictates constant change and adapting to a new plan. And what is the first change in plan? Often this involves a delay or change in your maintenance schedule. Customer orders and Production needs can dictate plans or changes to your maintenance team. Very often it is canceled maintenance schedules or planned shutdowns that can be a quick solution for production needs. However, has your production team considered the real effect of changes to your maintenance planning? Unscheduled shutdowns compared to a planned maintenance program can influence production in numerous ways: equipment reliability, customer response & equipment audits, production capacity & planning, downtime, efficiency and availability. Preventative maintenance planning and coordinated support between maintenance & production will typically result in meeting production goals while maximizing equipment reliability and efficiency.

Submitted by WS Thermal

Heat Treat Tip #18

Snagged T/C Wire – Avoid It

Try not to use insulated thermocouple wire if you snag the insulation off the outerjacket along the length of the wire. This may cause the inner insulation to fail andcause low temperature readings.

Submitted by WS Thermal

Heat Treat Today is compiling the 2019 101 Heat Treat Tips list for the fall issue to be distributed at Heat Treat 2019, the biennial show from the ASM Heat Treating Society to be held in Detroit, Michigan, October 14-17, 2019. If you have a heat treat-related tip that would benefit your industry colleagues, you can submit your tip(s) to doug@heattreattoday.com or editor@heattreattoday.com.