![]() Happy Halloween! Instead of the spook, we wanted to give you something to celebrate this weekend the way YOU know how to: through heat treating. Whether you know a heat treater on a tight budget or your shop is ready to "try something new", we want to show you TWO uses of pumpkins for your shop this Fall.

Happy Halloween! Instead of the spook, we wanted to give you something to celebrate this weekend the way YOU know how to: through heat treating. Whether you know a heat treater on a tight budget or your shop is ready to "try something new", we want to show you TWO uses of pumpkins for your shop this Fall.

Pumpkins as Furnaces

Pumpkins as Furnaces

Pumpkins make great ovens. The orange gourds, commonly converted into jack-o-lanterns this late-October, have a proven degree of structural integrity that can maintain heat for one cycle.

This process works best for heat treating parts that need to be introduced to gaseous H2O during the cycle time.

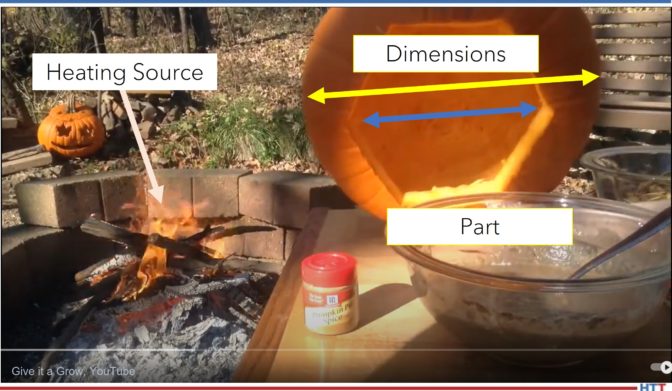

As you can clearly see below, the pumpkin can serve as a "furnace" for special parts.

- Dimensions: 11.5" outer diameter x 11" total height; heating chamber is 10.75" diameter x 10.25" height; wall thickness is 3/4"

- Temperature: range from 0-450 degrees Fahrenheit lasting 1 cycle (max)

- Materials: organic matter derived from Cucurbita pepo

Cycle times may vary depending on the size and quality of vessel. For the example used in this article, the cycle ranged from roughly 0.75-1.25 hours. Controls are not included.

Find more pumpkin furnaces from this Texas supplier.

Find more traditional atmosphere furnaces here.

Pumpkins as Heat Treated Parts

Pumpkins don’t just make great furnaces, they are also parts to be heat treated. If it's slow on the shop floor this Fall, just take a lousy pumpkin from your doorstep and get to work!

While a pumpkin does have more prep involved, word has it this “part” is edible, too. Follow these steps when these parts come to your shop:

- Be sure that the coating used for the part is of highest quality. Cinnamon, allspice, and a hint of salt with olive oil have the right chemical composition for this part.

- When applying the coating, it is imperative to evenly distribute it across all parts in order to achieve consistent, predictable results.

- I'll leave the heat treating to you, but I recommend an open flame furnace for these parts. In this instance, discoloration is to be expected, but this is typically what customers want to see. Bonus: No quenching or cleaning required.

- Transfer parts to a cooling location.

For best results, heat treat parts in small batches.

Videos in this feature:

Grilled Pumpkin Recipe For Halloween

Continuous atmosphere protection sintering heat treatment furnace