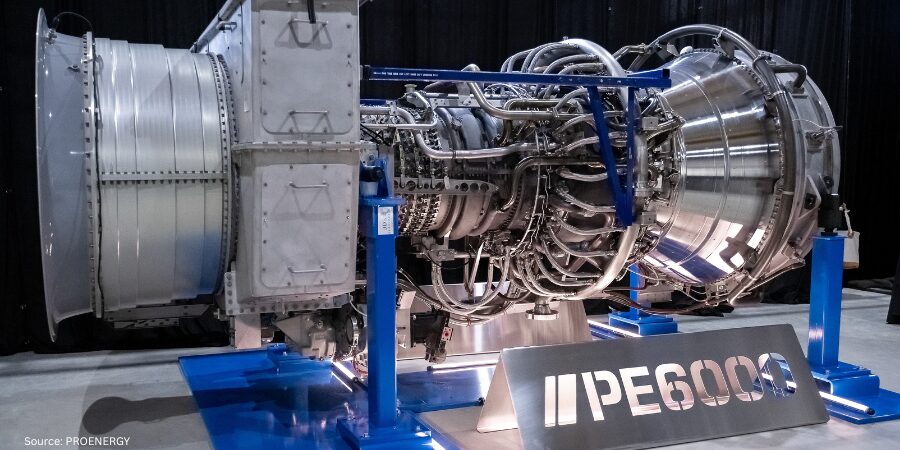

A company that services the aerospace industry has expanded its thermal processing capabilities with a new vacuum furnace, growing their operations into multinational thermal processing.

Managing Director

SECO/VACUUM

SECO/WARWICK has produced the vacuum furnace, which is customized to meet the rigorous heat treating standards of the aerospace industry, one of the industries they serve. As such, the 6-bar Vector is equipped for dual gas quench with nitrogen, argon, or any partial-pressure of the two, automatically set and maintained according to the batch recipe. It is also equipped with a high-vacuum system with a diffusion pump, key features for many aerospace-grade thermal processes.

Director of Operations, one of the family-business owners, stated, “Our ongoing success is powered by our partnership with SECO/WARWICK. This state-of-the-art furnace introduces advanced automation, ensuring faster turnaround times while maintaining the highest quality standards for our customers. Additionally, this new technology enhances our capabilities, granting us the confidence to enter new markets and secure new opportunities with exceptional reliability.”

“We never take that partnership for granted.” Piotr Zawistowski, Managing Director of SECO/VACUUM, responded.

This new Vector is horizontally configured with a 24x24x36 inch (600x600x900 mm) hot zone equipped for a payload of 1750lbs (800kg).

Press release is available in its original form here.