A United States military base will receive an electrically heated draw batch oven for use in heat treating aerospace components. The industrial oven was engineered to meet critical safety requirements and the stringent demands of aerospace heat treating.

Manufactured by Wisconsin Oven Corporation, the system features combination-style airflow that delivers both horizontal and vertical upward heat flow to ensure optimal heating rates and consistent temperature distribution across the product. Temperature uniformity has been verified through a Class 1 Temperature Uniformity Survey (TUS) conducted in accordance with pyrometry specification AMS 2750H, with achieved uniformity of ±5°F at 200°F, 700°F, and 1200°F.

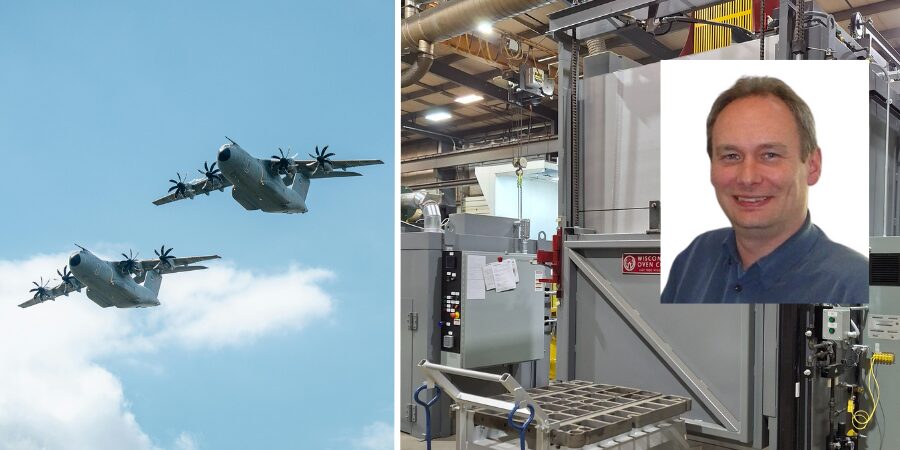

“This draw batch oven was designed with additional safety features for operators, tight uniformity, and compliance standards required by the U.S. Military. The temperature uniformity survey was performed prior to shipment to verify compliance with AMS 2750H Class 1 requirements,” said Doug Christiansen, senior application engineer.

The oven features “can” style construction with a heavy plate exterior and six inches of high-temperature insulation for durability and thermal efficiency. A custom portable load/unload cart allows operators to stage the load before heating and remove it for cooling.

The UL508A-certified control panel includes a Eurotherm 3504 programmable temperature controller with advanced auto-tune and Ethernet communication. It also features a high-limit instrument to prevent over-temperature conditions, along with low-voltage calibration TC jack plugs and a variable frequency drive for the recirculation blower.

Press release is available in its original form here.