Heat Treat Today offers News Chatter, a feature highlighting representative moves, transactions, and kudos from around the industry. Enjoy these 14 news items, including Haynes International Inc.‘s new hydraulic radial forging line to boost production of high-performance nickel- and cobalt-based alloys, the acquisition of JSA/Metalline by Hubbard-Hall Inc. to expand metal finishing service capabilities across the Midwest, Bodycote‘s achievement of independent validation from Bureau Veritas for its carbon footprint calculator tools, and more!

Equipment

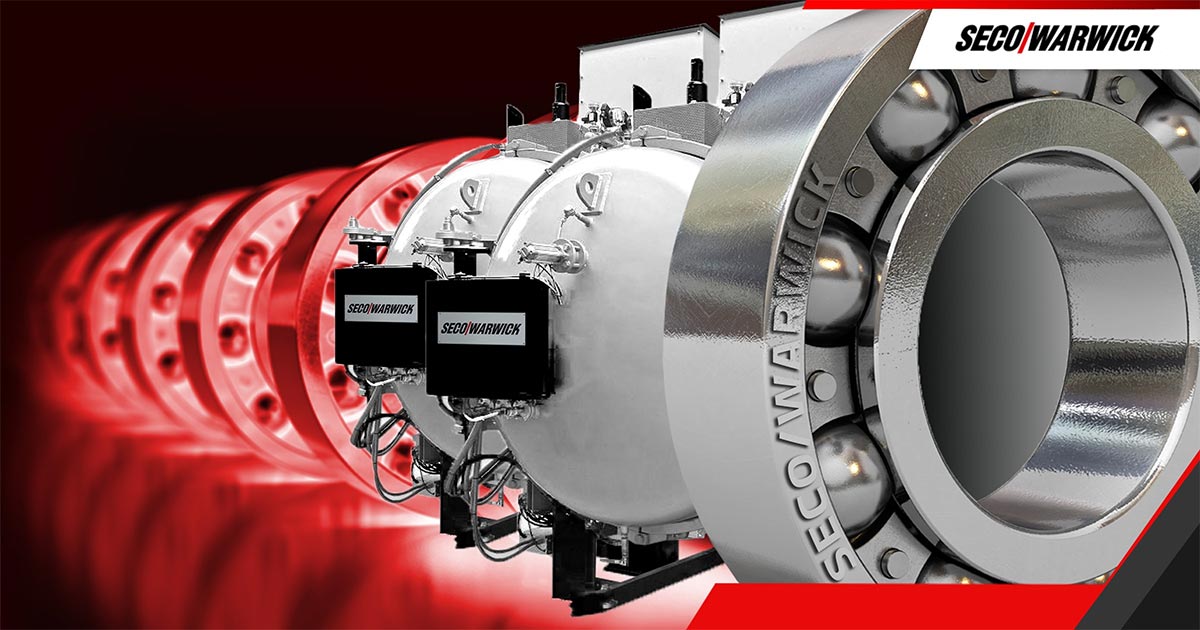

1. A major U.S. bearing manufacturer has ordered two advanced SECO/WARWICK USA vacuum heat treat furnaces, reinforcing its commitment to precision manufacturing and capacity growth. The investment supports rising demand across the bearing industry, where consistent metallurgical performance is critical for industrial and aerospace applications.

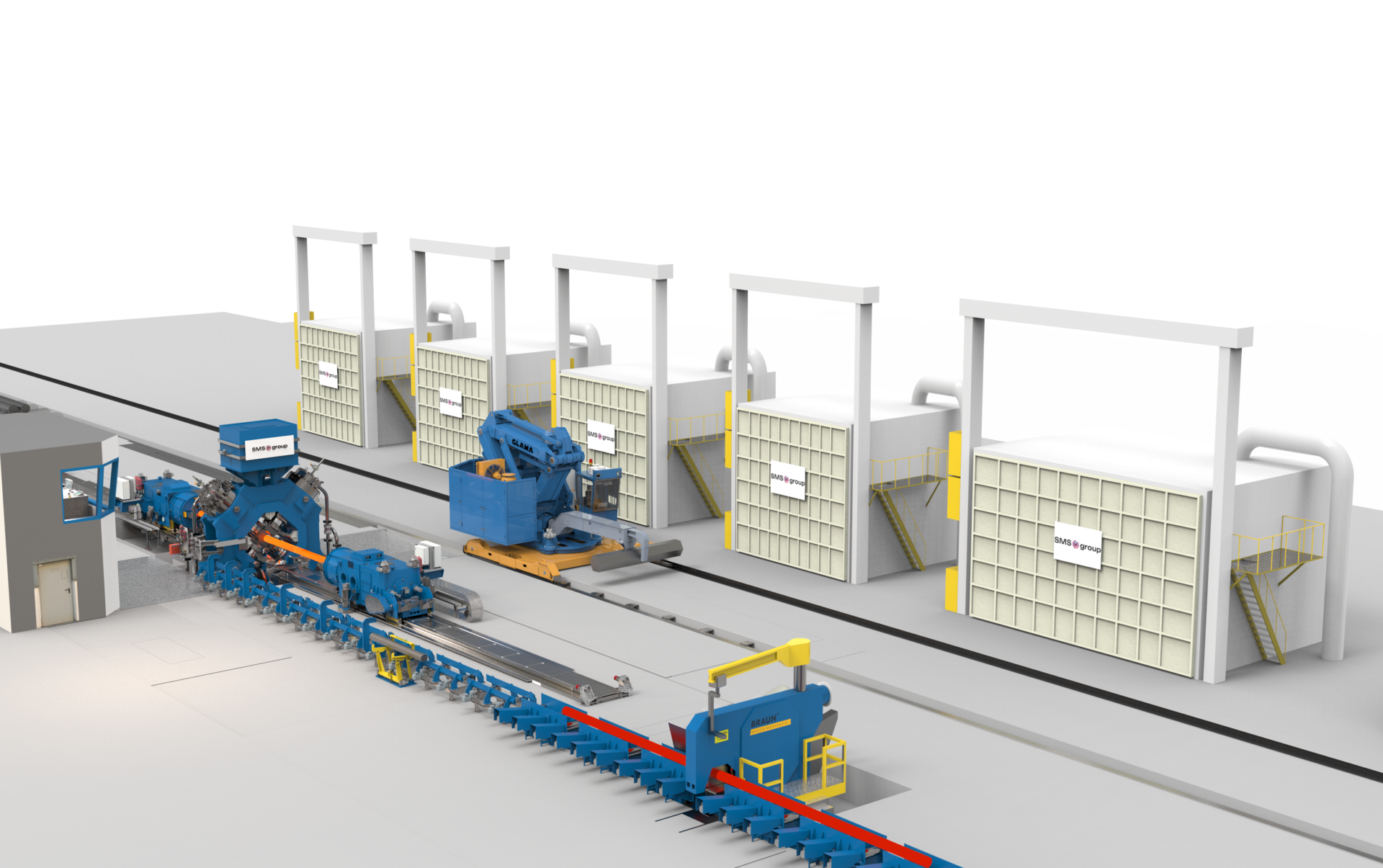

2. Haynes International Inc. has commissioned SMS Group to supply a new hydraulic radial forging line to increase its production of nickel- and cobalt-based alloys, serving markets such as aerospace and chemical processing in the United States. The integrated plant investment, which includes a forging machine, reheating and annealing systems, and automated material handling, is expected to improve production efficiency, metallurgical quality, and responsiveness to global demand while supporting growth in high-performance alloy manufacturing.

3. Hertwich Engineering GmbH has delivered a customized rolling ingot foundry — including an Ecomelt PS120 preheat-shaft melting furnace, holding furnace, and vertical casting machine — to Remi Claeys Aluminium N.V. The new facility, set to begin operations in spring 2026, will enhance process stability and efficiency for processing contaminated aluminium scrap, strengthening competitiveness and sustainability in the aluminium manufacturing sector.

4. Marle Group has purchased and will install an additional vacuum heat treating furnace at its Marle Nowak facility in Pancé, France, expanding in-house capacity for heat treating cobalt-alloy orthopedic implants and surgical instruments. Supplied by SECO/WARWICK, the new furnace responds to the Marle Group’s need for rapid cooling of large loads while supporting efforts to improve production control and delivery times for medical device manufacturing.

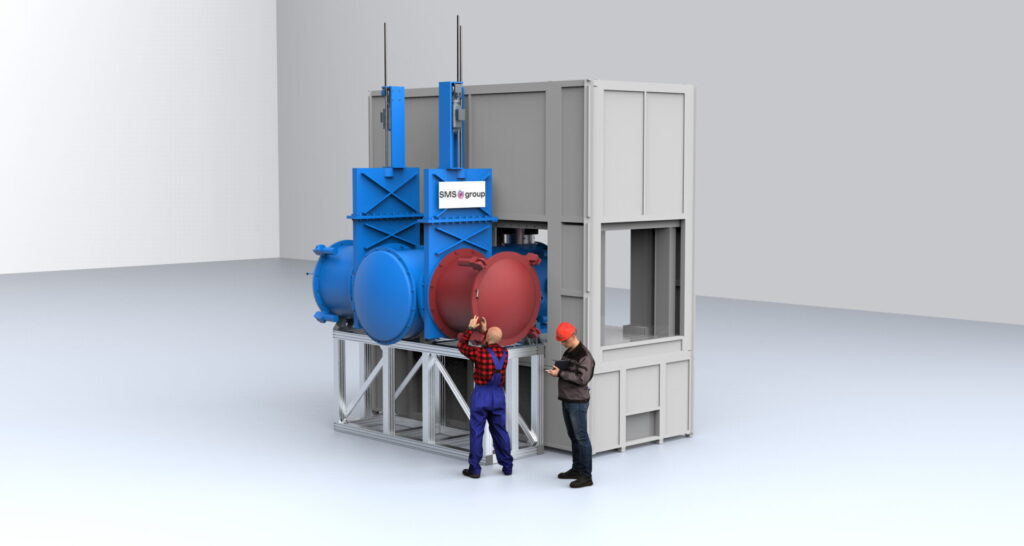

5. SMS group is supplying an isothermal forging module to the Institute of Forming Technology and Machines (IFUM) at Leibniz University Hannover to be integrated into their existing press as part of the EU and Lower Saxony-funded “High-performance materials of the future – oWZu” research project. This advanced vacuum forging system will expand research and development of high performance materials for aerospace, medical technology, and industrial applications, accelerating technology transfer and setting new standards in forming reactive superalloys.

6. Researchers at the Korea Institute of Energy Research (KIER) have developed an electrified heat treatment technology for the annealing stage in galvanized steel strip production that cuts greenhouse gas emissions by over 98% compared with traditional combustion furnaces. The breakthrough replaces fossil fuel burners with electric heating elements while maintaining product quality and productivity, and could significantly reduce equipment costs and support decarbonization in the automotive and appliance steel supply chain. This innovation advances industrial heat treating processes toward carbon-free operation, helping manufacturers meet tightening environmental standards and global decarbonization goals.

7. SECO/WARWICK has been selected by Brazil’s Isoflama to supply a customized horizontal retort furnace for high-temperature tempering and ZeroFlow nitriding at its heat treatment plant. This new furnace will integrate with Isoflama’s production control system and support processing of large, heavy components, enhancing efficiency and precision to continue serving the automotive, aerospace, and machinery industries in South America.

8. Brugola has implemented CODIAC monitoring technology to ensure reliable tracking and analysis of furnace processes on AICHELIN cast link belt furnaces at its facility. This upgrade enhances real-time oversight of thermal processing parameters, supporting consistent quality and operational efficiency.

Company & Personnel

9. Hubbard-Hall Inc. has acquired the assets of JSA/Metalline, bringing JSA’s customer-facing team into Hubbard-Hall’s organization to expand sales coverage, technical support, and response times for manufacturers serving the plating and general metal finishing industries across the Upper Midwest/Midwest. The move strengthens regional service capabilities, giving manufacturers more direct access to supplier expertise, streamlined single-source ordering, and stronger technical support for critical surface finishing processes.

10. AECO Corp. has promoted Maryann Remner to president, effective immediately, where she will lead the company and its three operating subsidiaries — Alloy Engineering, Mach3 Machining, and Thermcraft — which serve high-temperature fabrication, precision machining, and thermal processing equipment markets.

11. Castings Technology, a UK manufacturer of titanium and steel castings, has announced the creation of twenty new jobs as it expands capacity to meet growing aerospace demand, reinforcing its role in supplying cast components for the sector.

12. WINGENS CONSULTANTS has appointed Mark Hemsath as Executive Consultant – Heat Treat & Advanced Furnace Specialist. Hemsath brings over 30 years of aerospace heat treating experience, with deep knowledge in vacuum systems, nitriding processes, and advanced furnace technologies.

Kudos

13. Bodycote has achieved independent validation from Bureau Veritas for its proprietary carbon footprint calculator tools covering nine core heat treatment processes, enabling customers to request ISO-assured carbon data for thermal processing methods such as vacuum and low-pressure carburizing. This validation enhances transparency and helps manufacturers measure and compare emissions, supporting the selection of lower-carbon heat treatment options.

14. Ipsen recognized six service technicians — Todd Jones, Casey Guinn, Craig Monaghan, Eric Gould, Alfredo Mendoza, and Dom Wirthlin — for completing its 14-week Field Service Engineer Academy, an intensive hands-on training program for vacuum furnace specialists combining classroom instruction with mentored field experience.