Heat Treat Today offers News Chatter, a feature highlighting representative moves, transactions, and kudos from around the industry. Enjoy these 14 news items, including OTTO JUNKER‘s induction furnace installation supporting low-carbon foundry operations, IperionX‘s collaboration with Carver Pump Company to strengthen domestic titanium manufacturing, Solar Atmospheres of Michigan earning its Nadcap 18-month Merit Status for heat treating and brazing, and more!

Equipment

1. OTTO JUNKER has equipped Eisengießerei Th. Schultz with a MONOMELT coreless induction furnace, replacing a cupola and converting the foundry to electric melting. The system significantly cuts energy use and CO₂ emissions while demonstrating how induction technology is helping foundries transition to more efficient, low-carbon production.

2. A global drivetrain technology leader has selected NUTEC Bickley to supply a CQI-9–compliant isothermal annealing line for automotive component production. The new equipment strengthens heat treat quality and consistency, reflecting the industry’s continued investment in advanced thermal processing to support higher-performance drivetrains.

3. Newton Heat Treating has completed a major equipment upgrade, replacing steam accumulators that had been in service for 20 years in its uphill quenching/cold stabilization operation. The upgrade directly impacts the company’s aerospace processing capabilities, with many parts destined for optical components in space applications undergoing this critical heat treatment process.

4. Kaiser Aluminum Corp., a producer of heat treated, flat-rolled aluminum products, has completed a $25 million expansion and upgrade of its Trentwood rolling mill in Spokane Valley. This marks the latest phase of the company’s long-term strategy to increase heat treatment throughput for aerospace, automotive, and general engineering markets.

5. ArcelorMittal is advancing a major expansion in electrical steel production that includes a preparation line, a continuous annealing and varnishing line, and a slitting line — developments that reflect ongoing job growth and investment in industrial heat treating processes worldwide.

6. A United States military base will receive an electrically heated draw batch oven from Wisconsin Oven Corporation for use in heat treating aerospace components. The industrial oven was engineered to meet critical safety requirements and the stringent demands of aerospace heat treating.

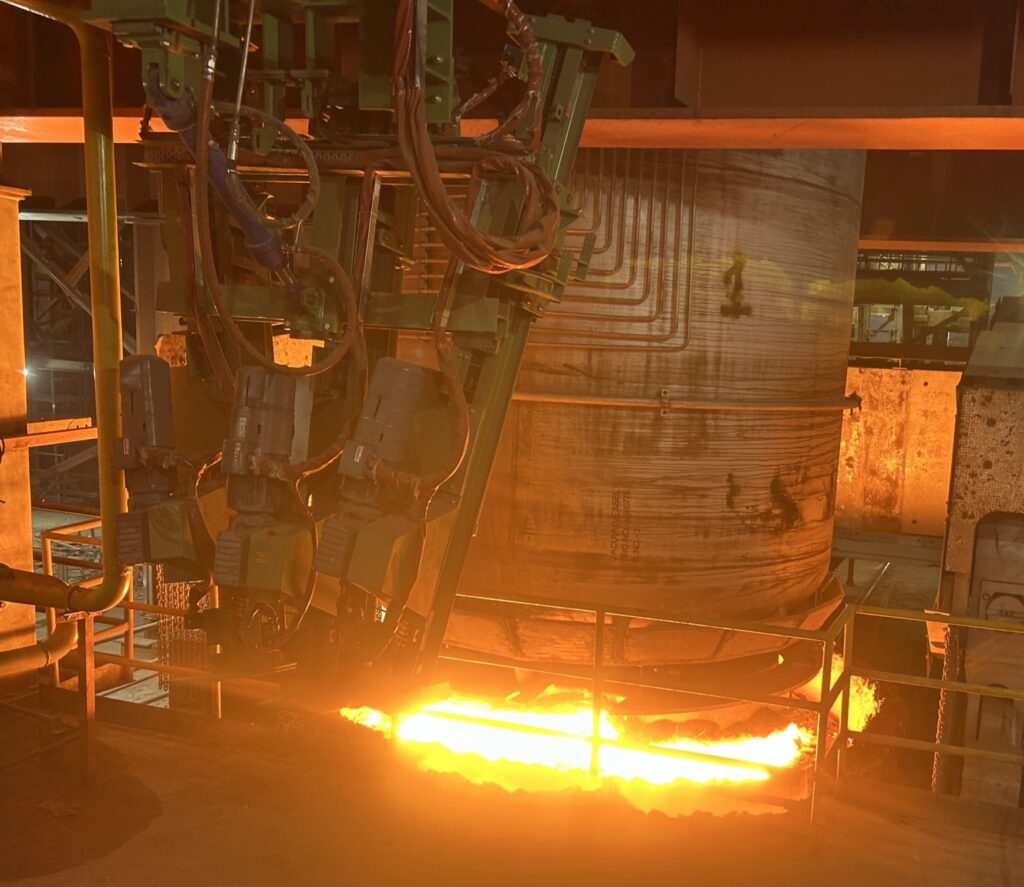

7. JSW Vijayanagar Metallics, a subsidiary of JSW Steel, has commissioned a new 350-ton RH (Ruhrstahl Heraeus) unit, the world’s first operational combination of an RH Ladle Rocker technology with Fast Vessel Exchange from SMS Group. This represents a major advancement in secondary metallurgy and plant efficiency.

8. PROENERGY has ordered four Ipsen vacuum furnaces for its new Houston location, expanding heat treating capacity to support growing demand for fast-start gas turbines and lifecycle maintenance services. The investment strengthens PROENERGY’s ability to manufacture, repair, and overhaul high-quality turbine components while reducing lead times.

Company & Personnel

9. SMS Group’s South Africa-based Metix brand and Magmec signed a memorandum of understanding to develop a magnesium metal production facility in the United Arab Emirates utilizing advanced reduction furnace technology. The facility will be designed to process magnesium oxide originating from feed sources such as dolomite or brine. The partnership aims to establish a regional, sustainable supply of magnesium for strategic industrial users.

10. Carlos Carrasco has joined the SECO/WARWICK USA sales team as regional manager for Mexico, bringing more than 11 years of experience with the company as a sales representative. In his new role, he will support customers across the region in addressing their heat treatment challenges.

11. IperionX is working with Carver Pump Company to advance domestic titanium manufacturing and thermal processing capabilities in a recent commitment to reduce long lead times for critical pump components used for naval shipbuilding. This addresses supply chain constraints that have slowed ship construction and maintenance. By shortening production timelines, the initiative supports improved fleet readiness while reinforcing domestic manufacturing capacity for mission-critical naval systems.

Kudos

12. Solar Atmospheres of Michigan has earned Nadcap 18-month Merit Status for heat treating and brazing, marking a significant quality milestone, bringing every Solar Atmospheres facility nationwide to merit standing. The achievement reflects three consecutive years of audits with zero major findings, underscoring the company’s disciplined process control and commitment to specification compliance while serving industries including aerospace, defense, and medical manufacturing.

13. Tenova hosted Indonesia’s Vice Minister of Industry, Faisol Riza, at its global headquarters to showcase sustainable steelmaking technologies, following an initiative led by Indonesian steel producer PT Tata Metal Lestari. The visit highlighted collaboration among Tenova, TML, and the Indonesian government to advance low-emission steel production, energy efficiency, and industrial innovation.

14. Bodycote has achieved Nadcap accreditation for heat treating, vacuum brazing, and TIG welding at its new 55,000-square-foot facility in Fairfield, Ohio. The milestone strengthens Bodycote’s North American presence and expands capacity to meet growing demand for high-specification thermal processing in aerospace, defense, and industrial manufacturing sectors.