In this Technical Tuesday installment, Neil Owen, general manager at Stresstech Inc., examines how BNA is redefining process verification across multiple industries by making quality control both traceable and measurable.

This informative piece was first released in Heat Treat Today’s December 2025 Medical & Energy Heat Treat print edition.

Heat treatment plays a crucial role in achieving the mechanical strength, fatigue resistance, and dimensional stability demanded of ferromagnetic steel components used in automotive, aerospace, energy, and heavy manufacturing sectors. From furnace batch carburizing to localized induction hardening, these processes are designed to produce precise microstructural transformations and stress distributions. Barkhausen Noise Analysis (BNA) has emerged as an effective method to confirm that these transformations have occurred uniformly across all parts and also detect subtle localized deviations.

Introduction

Verifying uniform microstructural transformations and stress distributions during critical heat treatment processes remains a challenge for quality control teams. Traditional verification methods, such as hardness testing, microstructural sectioning, and metallographic examination, are accurate but slow, invasive, and limited to a small area. Non-destructive alternatives, like eddy current or ultrasonic testing, provide some insight but often lack the sensitivity to microstructural and stress variations that accompany phase transformations. As manufacturers seek faster, data-driven approaches to verify furnace and surface heat treatment quality, Barkhausen Noise Analysis (BNA) has emerged as a highly sensitive and efficient solution.

BNA offers a non-destructive, microstructure-responsive means of assessing heat treatment performance, directly reflecting the metallurgical state of ferromagnetic materials. Its unique advantage lies in its sensitivity to both magnetic domain behavior and residual stress, which are influenced by the phase composition, hardness, and internal stress of the steel. This makes it an ideal verification tool for confirming that intended transformations — particularly the shift from softer ferritic or pearlitic microstructures to harder martensitic or bainitic phases — have occurred fully and uniformly.

The Barkhausen Noise Phenomenon

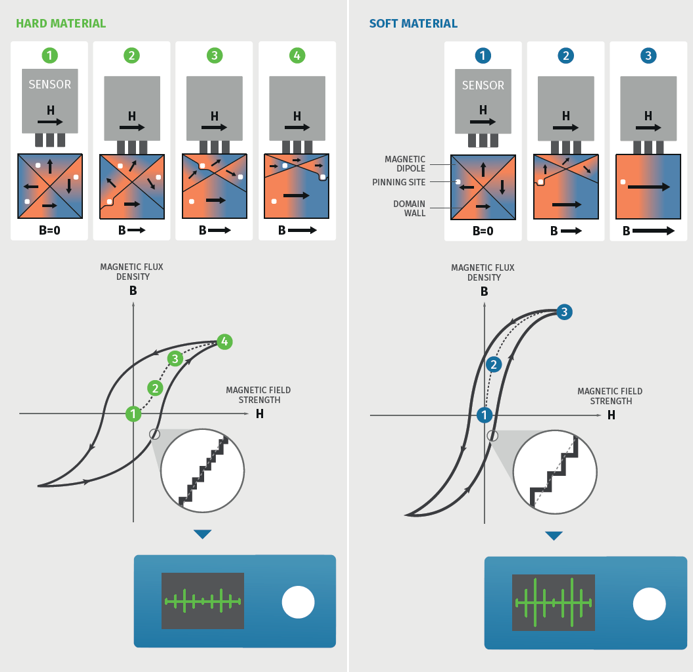

When a ferromagnetic material is subjected to a varying magnetic field, its magnetic domains (i.e., regions within the crystal lattice where magnetic moments are aligned) reorient in discrete jumps rather than continuously. Each jump releases a small electromagnetic pulse known as Barkhausen noise. The cumulative signal, measured as a function of applied field strength, provides a distinct magnetic “fingerprint” of the material’s condition.

Source: Stresstech Inc.

Hardness is related to the number of pinning sites (e.g., dislocations, precipitations, or other irregularities) in a material. When a magnetic field is applied to a ferromagnetic material, magnetic domain walls start to move. Domain walls collide with pinning sites in the material structure which impedes the domain wall movement. Magnetic domain walls move more easily in soft materials than in hard materials. Since hard materials contain numerous pinning sites, domain wall movements are more restricted. In soft materials, domain walls can make bigger jumps.

Because these parameters directly reflect the results of heat treatment, BNA provides a sensitive, immediate, and quantifiable indicator of metallurgical condition. When steel transforms from a soft ferritic–pearlitic structure to a hard martensitic one, the Barkhausen signal typically decreases by a factor of four to five, providing a clear signature of successful transformation.

Responsiveness to Microstructural Transformation

BNA is especially valuable because it responds directly to the magnetic consequences of metallurgical change. In untransformed ferritic–pearlitic steel, magnetic domains move freely, generating strong Barkhausen activity. As the microstructure transforms to martensite or bainite during quenching, domain wall motion becomes constrained by high dislocation density and lattice distortion, resulting in a lower, sharper Barkhausen response.

This distinct contrast enables this analysis to serve as both a quick verification tool and a diagnostic method. A simple contact check using a handheld probe can confirm within seconds whether a part or batch has achieved the target hardness and transformation state. Alternatively, an automated scanning or mapping inspection can reveal subtle variations caused by uneven heating, quenching, or post-process re-tempering and grinding.

Unlike many other non-destructive techniques, it requires no special surface preparation or coupling media. Measurements can be made directly on machined or ground surfaces, provided they are ferromagnetic and accessible. In some cases, BNA can also operate through coatings, such as HVOF chromium coatings on structural steel, and provide accurate insights. This makes it ideal for in-process verification, final inspection, and field assessments, supporting real-time process control and fast decision-making.

Comparison with Adjacent Verification Methods

While no single inspection method captures every variable, BNA occupies a distinctive position in the non-destructive testing landscape. Hardness testing provides a direct mechanical measure of strength but is destructive and slow. Eddy current techniques are fast but primarily respond to surface conductivity and hardness, not underlying microstructure. Ultrasonic methods are excellent for detecting internal flaws but less effective in distinguishing between tempered and hardened phases. X-ray diffraction remains the reference standard for residual stress measurement but is stationary, slower, and typically limited to laboratory use.

BNA bridges these gaps by offering metallurgical sensitivity, speed, and portability, making it an ideal complement to conventional hardness and microstructure testing and providing immediate feedback without sectioning or preparation. Several defining attributes are as follows:

- Fast — each measurement takes only seconds

- Non-destructive — contact-based, leaving no surface mark

- Microstructure-sensitive — reflects both phase transformation and stress state

- Portable and adaptable — usable in-line or in the field with handheld or robotic probes

Case Example 1: Induction-Hardened Camshaft Inspection for Heat Treatment Defects

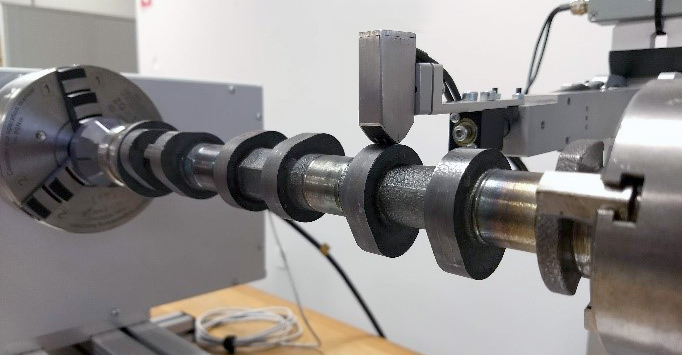

Camshafts undergo highly localized induction hardening to create a wear-resistant surface layer while maintaining ductility in the core. Variations in induction power, cleanliness from machining waste, coil positioning, or quench delay can lead to soft spots or over-tempered areas, which reduce fatigue life. Similarly, aggressive post-hardening grinding can cause thermal rehardening or burn damage, both of which affect local stress and hardness.

Source: Stresstech Inc.

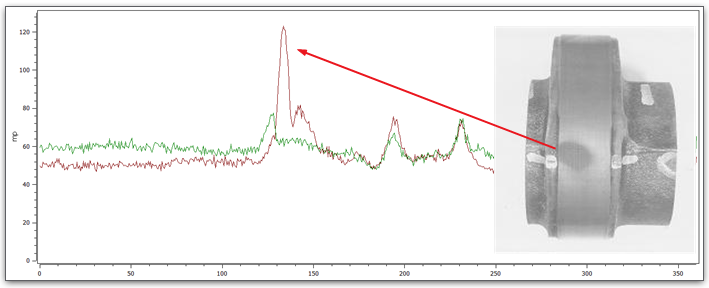

BNA provides a fast, non-destructive way to detect these variations. In one case, a powertrain manufacturer applied a line scan across each cam lobe using an automated BNA system. The resulting Barkhausen map revealed both high-signal areas (softer, grinding burned, re-tempered zones) and low-signal regions (hardened/normal zones).

Subsequent correlation with microhardness profiles confirmed that regions with elevated Barkhausen activity corresponded to localized softening due to heat treatment defects or rehardening from grinding burn damage, while areas with reduced response aligned to the master part readings that verify successful production of parts. This dual sensitivity allowed engineers to distinguish between heat treatment and surface finishing issues using a single technique.

Source: Stresstech Inc.

After integrating BNA into the inspection cell, the manufacturer reduced scrap and rework rates by over 25% through optimizing their production process based on resulting data, while gaining digital traceability for each camshaft. Automated result logging allowed process engineers to correlate defects with specific machine parameters, improving control and accountability across both induction and grinding stages.

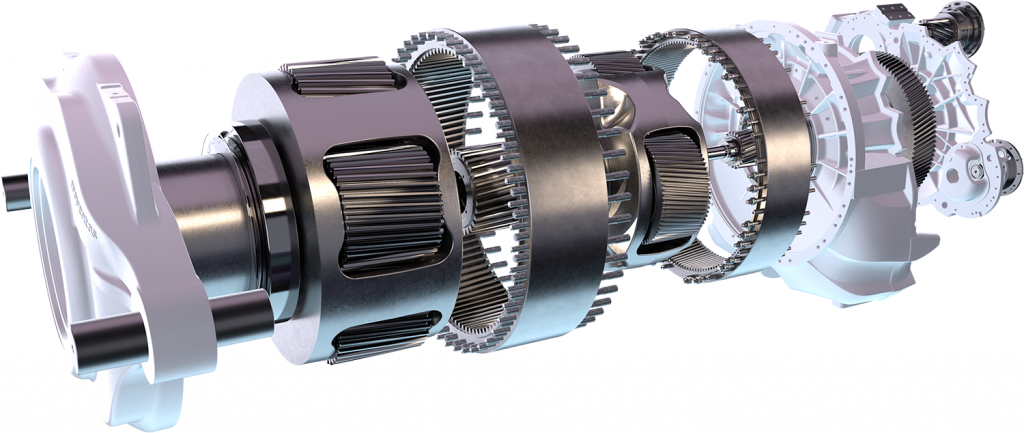

Case Example 2: Detecting Manufacturing Defects in Heat Treated Wind Turbine Gearbox components

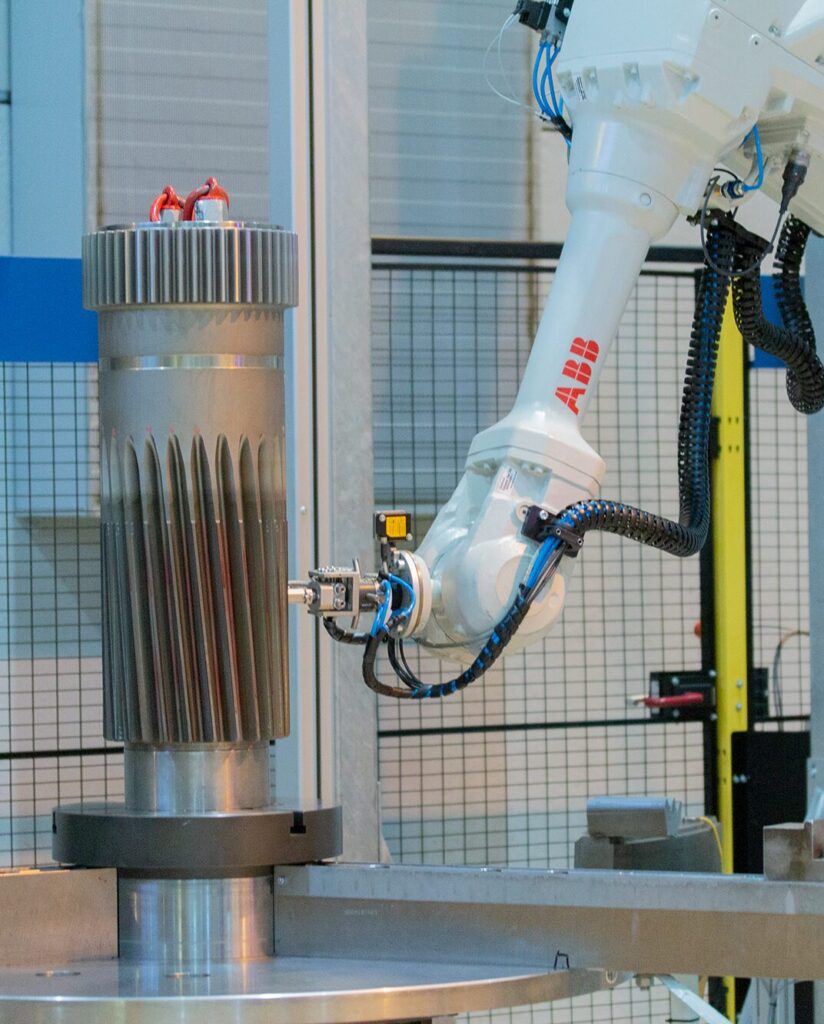

Moventas (now operating as Flender Finland Oy), an expert in wind turbine gearbox manufacturing, has been in the industry for 40 years and is passionate about innovating gearbox solutions that enable cost-savings & trouble-free operation. Over the past 30 years, starting from the very first Barkhausen system to the latest robotized system, Moventas has trusted their grinding inspection to Barkhausen noise measurement systems.

Source: Flender Finland Oy

Nowadays, wind turbine manufacturers require that surfaces of heat treated gears are also tested for the possibility of grinding burn. Grinding burn is a common name for thermal damages that occur on the surface during grinding processes following heat treatment. These burns cause local discolorations on the surface, and they can soften or harden surface layers and cause unwanted residual stress.

Nowadays, wind turbine manufacturers require that surfaces of heat treated gears are also tested for the possibility of grinding burn. Grinding burn is a common name for thermal damages that occur on the surface during grinding processes following heat treatment. These burns cause local discolorations on the surface, and they can soften or harden surface layers and cause unwanted residual stress.

Source: Stresstech Inc.

Moventas is an advanced BNA user and uses it beyond just sorting good samples to burnt ones.

Taisto Kymäläinen, quality manager at Moventas, explains that Barkhausen’s method allows for the early detection of damage, as BNA reacts in the smallest changes in a microstructure. As a result, it can be used to optimize a grinding process to find correct grinding parameters. For example, BNA can reveal flaws in cooling or grinding stone wear before actual burn appears.

This means that with critical energy applications, BNA can be relied upon as a complete non-destructive testing technique when looking at microstructure consistency and integrity.

As BNA can identify consistent and accurate heat treatment characteristics of components, as well as additional damage caused during the manufacturing process, it is often relied upon as a crucial quality control check to verify each component in critical applications. Since BNA is a comparative method, users need to determine acceptable levels for their products with the master sample procedure. The master sample procedure can be validated with X-ray diffraction measurements or nital etching, for example. When the master sample procedure is set, BNA is an accurate method to detect microstructure changes.

This method has now become widely utilized by the energy sector as an established testing method, which is gaining widespread adoption by OEMs and operators as the gold standard of quality control inspections of critical components across their technologies.

Integration into Quality Systems

Modern Barkhausen measurement platforms combine precise sensing with digital analysis, providing traceable, repeatable, and operator-independent quality data. Results can be stored locally or integrated into manufacturing execution systems (MES) and quality management systems (QMS) for statistical process control and long-term trending.

Because of its portability and speed, BNA supports a range of industrial inspection strategies:

- In-process verification of heat treated batches or ground components

- Incoming inspection of hardened parts from suppliers

- Failure analysis and field verification during maintenance and overhaul

When used alongside hardness or residual stress testing, this inspection technique enriches process understanding by revealing how microstructure, hardness, and stress interact. It transforms heat treatment verification from a subjective evaluation into a quantitative, magnetic-domain-based diagnostic of material integrity.

Conclusion

BNA provides a unique combination of speed, non-destructiveness, and metallurgical sensitivity for verifying heat treatment performance in ferromagnetic steels. Its fundamental sensitivity to magnetic domain wall mobility allows it to distinguish between soft, untransformed ferritic–pearlitic structures (high signal) and hard, fully transformed martensitic or bainitic phases (low signal).

For furnace batch processes, this technique delivers rapid confirmation that complete transformation has occurred and that quenching uniformity has been achieved. For localized induction-hardened or ground components, it identifies heat treatment defects, soft spots, and grinding-related damage in a single inspection.

As manufacturers pursue smarter, faster, and more traceable quality control systems, BNA is a practical bridge between metallurgical science and modern production efficiency, providing a magnetic fingerprint that reveals the true structural and stress condition of steel components.

About The Author:

General Manager, Stresstech Inc.

Neil Owen serves as the general manager of Stresstech Inc. (Americas), based in Pittsburgh, PA. He helps manufacturers and researchers apply Barkhausen Noise Analysis and X-ray diffraction for heat treatment verification and quality control. With hands-on and leadership experience, he bridges advanced NDT with production needs in aerospace, automotive, and related critical sectors across the Americas.

For more information: Contact Neil at Neil.Owen@stresstech.com or LinkedIn.