In today’s News from Abroad installment, we highlight several major global developments — from digital furnace upgrades at a steel producer to new aluminum smelter plans and modernization projects at rolling mills and galvanizing lines.

Heat Treat Today partners with two international publications to deliver the latest news, tech tips, and cutting-edge articles that will serve our audience — manufacturers with in-house heat treat. Furnaces International, a Quartz Business Media publication, primarily serves the English-speaking globe, and heat processing, a Vulkan-Verlag GmbH publication, serves mostly the European and Asian heat treat markets.

Digital Upgrade to Strengthen Furnace Control at SSAB’s Finnish Site

“SSAB has selected Fives to modernise the control system of the reheating furnaces at its Raahe site in Finland…SSAB will implement the latest-generation Level 2 control system. The thermal optimiser, Virtuo-R, proposed by Fives, will automate furnace control with precise regulation, significantly reducing manual intervention and ensuring consistent results.”

“Smart Monitoring…will consolidate operational data…through intuitive dashboards. The system will provide real-time performance indicators, enable proactive process and quality monitoring, detect anomalies, and anticipate maintenance needs to enhance both performance and reliability.”

Read more: “Fives Digital Technology to Upgrade SSAB’s Furnace Control” at furnaces-international.com.

Ambitious Aluminum Smelter Project in Ethiopia

“RUSAL has signed a memorandum of understanding with Ethiopian Investment Holdings (EIH) to initiate a large-scale aluminium smelter plant in Ethiopia. The facility is estimated to have an annual production capacity of 500,000 Mt, positioning Ethiopia as a competitive supplier for both regional and global markets. The project is designed to meet growing domestic demand, support industrial development, and significantly reduce foreign currency outflows currently spent on aluminium imports.”

Read more: “RUSAL’s Ethiopian Smelter Project” at furnaces-international.com.

Hot-Mill Modernization Boosts Aluminum Processing Capacity

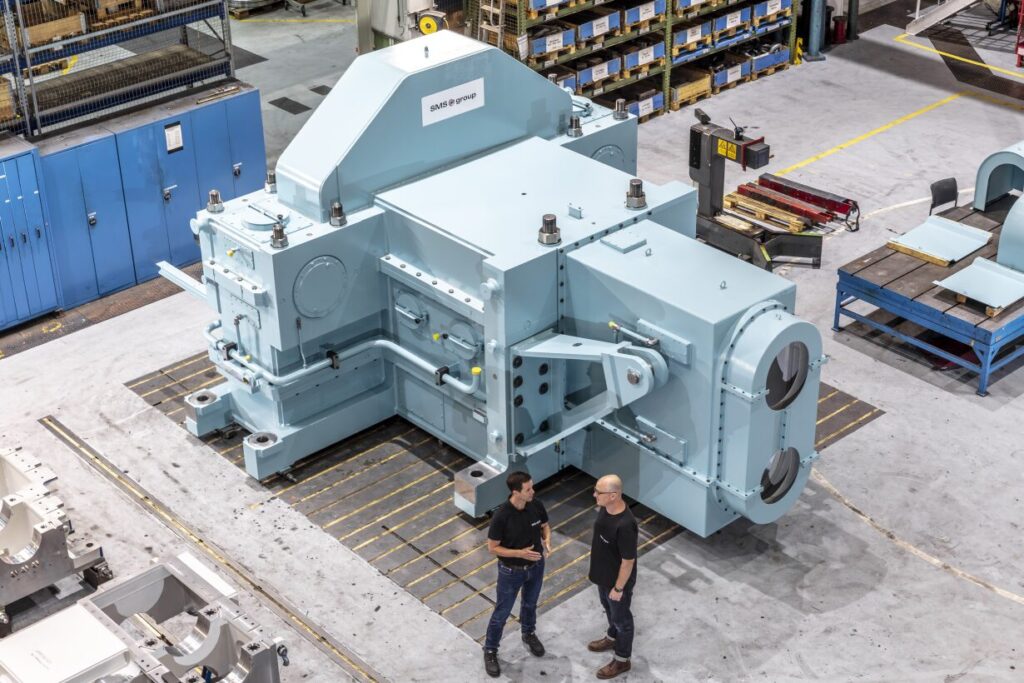

“For Gulf Aluminium Rolling Mill B.S.C. (GARMCO), a leading aluminum producer based in Manama, Kingdom of Bahrain, SMS group has successfully upgraded the motors and drives in the one-stand reversing hot rolling mill, originally built by a third-party rolling mill supplier…The novel drive system, built to deliver 20 percent higher torque compared to the mill’s original design capacity, has restored GARMCO’s hot rolling mill to full operational capacity and positioned it as a future-ready facility capable of advancing research and development in aluminum hot rolling.”

“The equipment is tailored to meet the rigorous demands of GARMCO’s operations, which include the production of aluminum coils, tread plates, slit coils, and foils for diverse industrial applications such as packaging and heat exchange systems.”

Read more: “SMS Group Expands Aluminum Processing at GARMCO Through Modernization of the Hot Rolling Mill” at heat processing.

New Hot-Dip Galvanizing Line for Ultra-High-Tensile Steel

“Japanese leading steel producer JFE Steel Corporation has placed an order with Primetals Technologies for a new continuous galvanizing line (CGL) at the West Japan Works in the Fukuyama district.

“With alloying capabilities, the new CGL is designed to support the automotive industry’s production of ultra-high-tensile steel sheets, which are crucial for reducing vehicle weight, meeting stricter environmental regulations, and enhancing collision safety standards.”

Read more: “Primetals Technologies Awarded Contract for Hot-Dip Galvanizing Line at JFE Steel” at heat processing.