Michigan Heat Treater Completes Building Expansion

Advanced Heat Treat Corp. (AHT) has completed a building expansion at their Monroe, Michigan facility. The new 6,000 sq. ft. addition increases production capacity and enhances operational efficiency.

The climate-controlled addition will provide an area for additional equipment and services for Advanced Heat Treat Corp. (AHT), free of existing production space, and provide a new office and modern breakroom.

Plant Manager

Advanced Heat Treat Corp.

Groundbreaking for the project took place on November 27, 2024 and their certificate of occupancy was awarded on July 29, 2025.

“Seeing this expansion completed is incredibly rewarding—it reflects the hard work and dedication of our entire team,” said Chad Clark, Plant Manager. “The additional space allows us to streamline operations, support more equipment, and enhance service to our customers. We’re excited to begin the transition and fully integrate the new area into our daily workflow.”

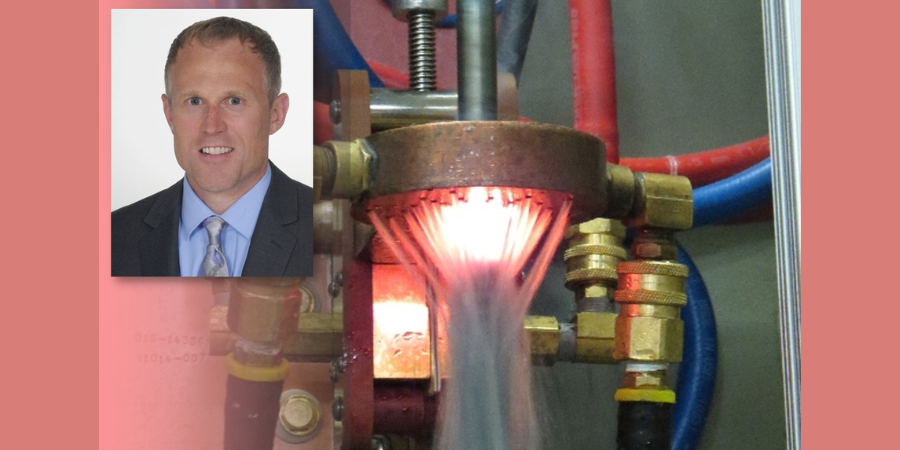

Heat Treat Today reported on a new gas nitriding unit at the Monroe facility last month. The new unit will be utilized in heat treatment for industries such as automotive, government and defense, plastics, power generation, and others. It will utilize UltraGlow® Gas Nitriding, which is a case-hardening process whereby nitrogen is diffused into the surface of a solid ferrous alloy by holding the metal at a suitable temperature in contact with a nitrogenous gas, usually ammonia.

AHT has four locations: one in Monroe, Michigan; two in Waterloo, Iowa; and a fourth in Cullman, Alabama. AHT Michigan has the unique capability to nitride parts up to 31-feet in length.

Press release is available in its original form here.

Find heat treating products and services when you search on Heat Treat Buyers Guide.Com

Michigan Heat Treater Completes Building Expansion Read More »