![]() "We want to make sure our customers succeed, and we do that by bringing our unique approach to every job." These are words that describe the mission of Paulo, a company whose areas of expertise reside in heat treating, brazing and metal finishing.

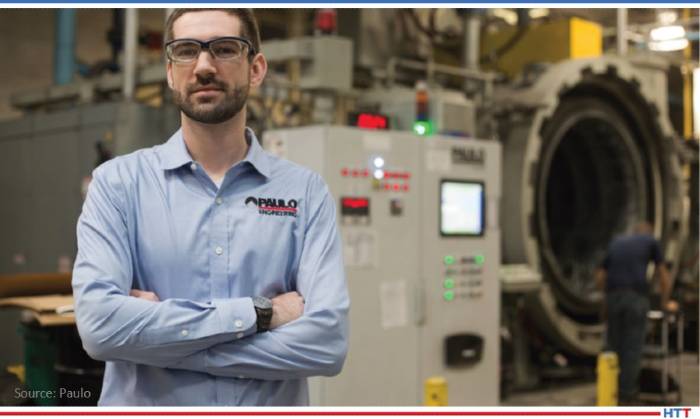

"We want to make sure our customers succeed, and we do that by bringing our unique approach to every job." These are words that describe the mission of Paulo, a company whose areas of expertise reside in heat treating, brazing and metal finishing.

A family business founded in 1943 by Ben and Pauline Rassieur in St. Louis, Missouri, Paulo now employs 400 people and provides almost every form of heat treatment as well as zinc plating and phosphating, black oxide, brazing, and hot isostatic pressing (HIP)—their most recent addition.

The company’s large metallurgical engineering staff performs testing, process development and improvement, and compiles metallurgical reports. Through the strategic location of their six facilities and the varied processes offered, they are equipped to partner with organizations up and down the supply chain to handle everything from overnight tool and die work to millions of pounds of production work for a variety of industries all with the support of their control systems and built-in contingency planning.

A few of the services they offer are through hardening, carburizing, nitriding/FNC, solution treating/aging, austempering, and HIPing. A few of the equipment capabilities include integral quench, mesh belt, vacuum, tip-ups, and HIP.

An important heat treating capability that helps them to succeed in the company’s mission is the ability to collect data and control furnace conditions in order to deliver consistent repeatable results. Additionally, as the largest privately held heat treater in North America, they can invest to support customer’s growth as they did recently in Monterrey, Mexico, announcing a large expansion that will double the square footage.

Paulo has heat treated interesting and memorable parts, from those used in space and on airplanes to those that supported PPE during the pandemic. Two that had big impacts on the company’s trajectory was the brazing of 106mm artillery shells and fuel pump housings.

"Datagineering" is a word the company created to explain the blending of the best in automation, data, and human expertise. As they look to the future, their continued implementation of the company-coined verb will aid in supporting customers, continuing overall improvement, and developing technically to push boundaries and deliver the best results.