Auto, Aero, Oil & Gas, Energy Industries to Benefit from Specialty Chemicals Acquisition

A global leader in primary and metalworking industrial process fluids recently announced an agreement to acquire the operating divisions of a UK company that provides specialty chemicals, operating equipment, and services to industrial end markets.

Quaker Houghton plans to purchase Norman Hay plc, which serves a number of industries including aerospace, automotive, oil and gas, and power generation through four divisions:

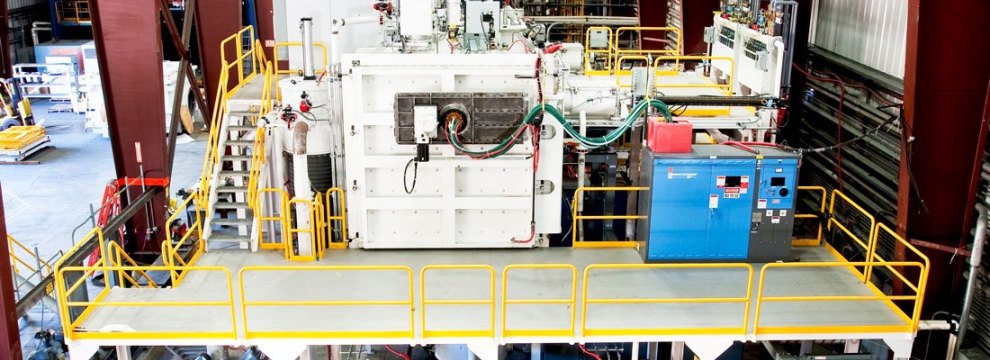

- Ultraseal, a leading global provider of impregnation technology, including porosity sealants, and associated chemistry and equipment for die cast components;

- SIFCO ASC, a leading global provider of surface treatment solutions through selective electroplating, anodizing, chemical solutions and engineering solutions;

- Surface Technology, a specialty provider of surface treatment solutions including coatings, thermal sprays, plating and other ancillary services; and

- Norman Hay Engineering, a leading provider of design and engineering services that support surface treatment plants and equipment for the Ultraseal, SIFCO ASC and Surface Technology businesses as well as additional third-party industrial engineering applications.

Quaker Houghton intends to operate the acquired divisions as a stand-alone business within its Global Specialty Businesses platform while it completes the integration of Quaker Chemical and Houghton International.

“This acquisition represents an opportunity to add new technologies with good growth characteristics in attractive core market segments with high barriers to entry such as die-casting, automotive OEM and aerospace,” said Michael F. Barry, chairman, CEO, and president of Quaker Houghton. “We also believe it provides a strategic opportunity to take advantage of external market trends such as the light-weighting of vehicles and 3D printing where we have the opportunity to leverage our global footprint and complementary geographic strengths. In addition, Norman Hay’s engineering expertise, which includes robotics applications, strengthens the existing equipment solutions platform inside Quaker Houghton and further positions the Company for Industry 4.0.”

Norman Hay plc was established in 1946 as a decorative electroplating business and has evolved into a global specialty chemicals sealant, surface coatings, and engineering group. The company is headquartered at its modern, state of the art production facility in Coventry, England. The company has approximately 400 employees with production and R&D facilities across Europe and the United States.

Main images photo credit: video stills, Quaker Houghton

Auto, Aero, Oil & Gas, Energy Industries to Benefit from Specialty Chemicals Acquisition Read More »